Ⅰ. What is Masonry Paint/Stone Paint?

1.1Definition of Masonry Paint/Stone Paint

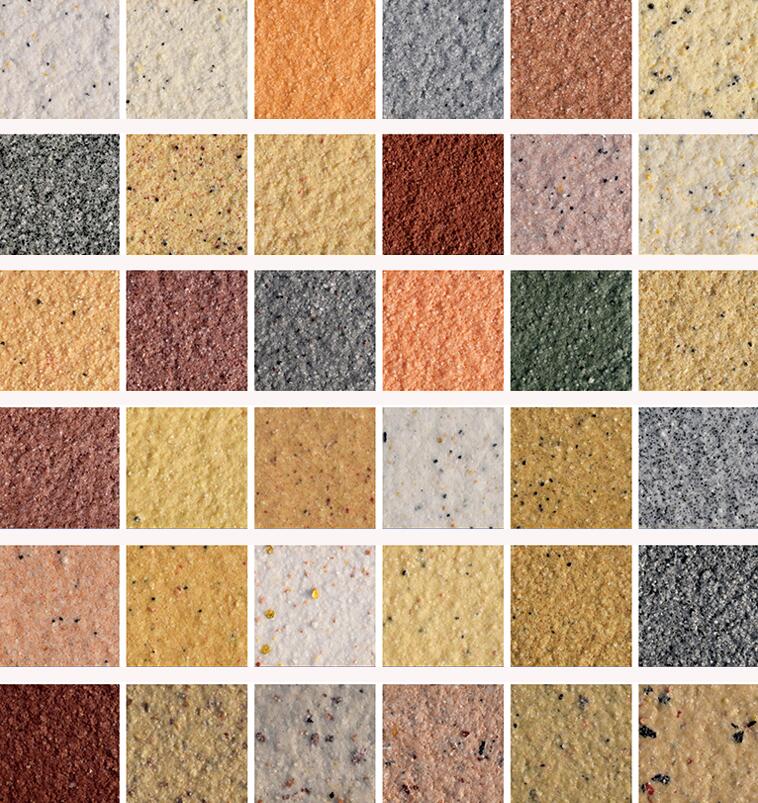

Natural stone paint is a water-based architectural decorative coating primarily composed of natural colored sand as the main aggregate, synthetic resin emulsion as the base material, and various additives. Its core feature is the ability to realistically mimic the texture, color, and tactile quality of natural stone. It is primarily used for exterior wall decoration in buildings and can also be applied for interior decorative accents.

1.2 Challenges in Stone Paint Liquid Filling

1. Particle Settling and Blockage Issues

The core component of natural stone paint is natural colored sand, with particle sizes typically ranging from 0.1 to 3 mm. Since its density is greater than that of the base resin emulsion, inadequate mixing before storage or filling can lead to particle settling and layering. During filling, settled large particles may block the filling nozzle, pipes, or valves, causing filling interruptions and requiring frequent shutdowns for cleaning, severely impacting production efficiency. Additionally, blockages may cause sudden pressure increases, leading to material splashing or measurement errors.

2. Difficulty in controlling metering accuracy due to high viscosity

Natural stone paint is a high-viscosity fluid with non-Newtonian fluid characteristics. During filling, the material encounters high flow resistance in the pipeline, resulting in unstable flow rates:

In the initial stage, due to the material being stationary in the pipeline, the viscosity is relatively high, and the flow rate is slow, which may lead to insufficient filling volume;

During continuous filling, increased shear force reduces viscosity and accelerates flow rate, potentially causing overfilling;

Viscosity differences between batches of natural stone paint further exacerbate fluctuations in metering accuracy, making it difficult to ensure consistent weight per barrel.

3. Material splashing and residual contamination

Natural stone paint has high viscosity and contains particles, making it difficult to “cut off” when flowing from the filling nozzle, often resulting in “tailing” or dripping, which contaminates the outer walls and openings of the packaging barrels, requiring additional manual cleaning, thereby increasing process costs; Additionally, material residues can accumulate on the inner walls of the filling nozzle and in pipeline dead corners, hardening and forming lumps over time. This not only affects the purity of subsequent fillings (as old residues mix with new material) but also increases the risk of blockages.

4. Difficulty in maintaining uniformity of composition

The decorative effect of natural stone paint relies on the uniform mixing of colored sand particles and emulsion. If the composition is uneven during filling (e.g., excessive or insufficient particles in certain areas), it can lead to variations in color and texture within the same batch of products, affecting the construction outcome. However, during filling, insufficient mixing force from the equipment and inconsistent flow rates within the pipes (e.g., slower flow near the pipe walls and faster flow at the center) may cause the material to re-stratify before filling, resulting in uneven particle distribution in each filled bucket and the occurrence of the “spotted bucket” phenomenon.

5. Severe equipment wear and high maintenance costs

Natural colored sand has high hardness (e.g., quartz sand with a Mohs hardness of 7). During the filling process, when the material flows at high speed, the particles continuously erode the inner walls of the pipes, filling nozzles, valve seals, and other components, accelerating equipment wear:

Wear on the inner walls of the pipes may cause material leakage, affecting the production environment;

Wear on the filling nozzle can enlarge its diameter, further reducing measurement accuracy;

Seal failure due to aging requires frequent replacement, not only increasing spare part costs but also reducing production efficiency due to downtime for maintenance.

II. Key Elements and Liquid Filling Solutions for Successful Filling

2.1. Continuous and Effective Mixing:

Pre-filling mixing: Before filling, the real stone paint in the storage tank must be thoroughly mixed to ensure consistency between the upper and lower layers of material. A powerful mixer is typically required.

Mixing during filling:

In-line Mixers: Install in-line mixers (such as static mixers or dynamic mixers) in the filling pipeline (typically at the storage tank outlet or near the filling head) to continuously shear the material and prevent sedimentation and layering within the pipeline.

Hopper Mixing: For gravity filling systems or those using intermediate hoppers, the hopper must be equipped with a mixing device (such as low-speed paddles) to stir and prevent sedimentation continuously.

Purpose: To ensure that the material filled into each packaging drum has consistent sand particle distribution and viscosity.

Selecting the appropriate filling pump:

Key requirements: Wear-resistant, shear-resistant, capable of conveying high-viscosity particulate materials, unlikely to clog, and easy to clean.

2.2. Commonly used filling pump types:

Peristaltic pump (hose pump): Very commonly used and recommended.

Advantages: Material only contacts the inner wall of the hose, no valves or seals, less prone to clogging; low shear force, less likely to damage material structure; strong self-priming capability; easy to clean (replace hose or backflush); relatively accurate metering.

Disadvantages: Hose is a consumable part requiring regular replacement; limited pressure; higher cost for high flow rates.

Pneumatic double diaphragm pump:

Advantages: Can handle materials with large particles and high viscosity; No mechanical seals, reducing the risk of leakage; good self-priming capability; relatively simple structure.

Disadvantages: Significant pulsation, which may affect filling accuracy and stability; diaphragms and ball valves are prone to wear; high compressed air consumption; relatively difficult to clean.

Plunger pump:

Advantages: High pressure, stable flow rate, and high metering accuracy.

Disadvantages: Complex structure and high cost; valves and seals are prone to wear (especially with sand-containing materials); potentially high shear force; difficult to clean.

Gear pump:

Advantages: Stable flow rate, suitable for high viscosity.

Disadvantages: Highly sensitive to particulates; sand particles can severely wear gears and pump housings; typically not suitable for natural stone paint containing coarse sand.

Conclusion: Peristaltic pumps and pneumatic double diaphragm pumps are the most common choices for natural stone paint filling, with peristaltic pumps being more popular due to their low shear and easy cleaning characteristics.

2.3. Optimizing pipeline design:

Pipe diameter: Select larger diameters (typically DN40 or above) to reduce flow resistance.

Material: Smooth and wear-resistant inner walls (e.g., ultra-high molecular weight polyethylene pipes, stainless steel pipes).

Layout: Minimize elbows, size changes, and dead corners; maintain a certain slope for easy drainage.

Shortening distance: Minimize the distance between the storage tank and the filling point.

2.4. Filling Head Design:

Large Diameter: Reduce flow resistance and prevent blockages.

Drip Prevention: Equip with pneumatic or electric shut-off valves for quick and complete closure to prevent dripping.

Adjustable Height/Insertable: Adapt to different drum heights or insert into the drum to reduce splashing.

Wear-Resistant Material: Parts in contact with the material must be wear-resistant (e.g., polyurethane, ceramic coating).

Optional scraper/bucket scraper: Reduces material buildup at the bucket opening.

2.5. Filling Method:

Gravity Filling: Material flows into the packaging bucket under its own weight. Suitable for lower viscosity materials or small-scale production. Ensure the height difference is not too small, as this can slow the flow rate. Less efficient for high-viscosity materials like natural stone paint.

Pressure Filling: Material is forced into the packaging bucket using pump pressure. This is the most widely used method.

2.6. Packaging Selection:

Bucket Mouth Diameter: Preferably select large-diameter packaging buckets for easier filling and reduced splashing.

Bucket Type: Square buckets offer advantages over round buckets in terms of stacking and transportation, but may be less convenient for filling.

Filling Environment and Operations:

Viscosity Control: Maintain appropriate temperature and adjust the formulation as needed to optimize filling performance.

Regular Inspection and Cleaning: After filling intervals or batches, thoroughly clean the pump, pipes, and filling nozzles to prevent residue hardening and blockages. Establish strict cleaning procedures.

Operator Training: Operators must understand the characteristics of natural stone paint and the key points of equipment operation, cleaning, and maintenance.

Protection: Wear protective goggles, gloves, etc., to prevent material splashing.

Ⅲ. SIGHTEC Auto Liquid Filling Machine for Stone Paint

3.1. Targeted Solutions for Core Pain Points in Stone Paint Filling

1. Completely Solves Sand Particle Sedimentation and Layering

Adopts a no-storage-tank design (No material tank), with materials flowing directly from the production platform to the filling head, eliminating any static storage stages. This fundamentally avoids sedimentation issues caused by differences in sand particle density in real stone paint. This design also reduces solvent evaporation (VOC reduction of over 30%), meeting European and American environmental standards.

2. Intelligent Algorithms Ensure Filling Accuracy

The machine is equipped with a self-learning optimization algorithm that dynamically adjusts filling parameters in real-time to accommodate fluctuations in natural stone paint viscosity and temperature changes. Tested accuracy far exceeds industry standards:

30kg drums: error margin of ±30g (national standard is ±50g)

5kg small drum: error of only ±15g (national standard is ±30g)

Based on an annual filling of 100,000 drums, this can reduce raw material loss by over 3,000kg (direct cost savings of approximately $15,000).

3. Outstanding flexible production adaptability

Quick switching between multiple bucket types: By replacing the modular filling valve, the system can accommodate both 30kg industrial buckets and 5kg small packaging buckets within 5 minutes, meeting the needs of fragmented orders.

Dual-efficiency production capacity: 30kg buckets at 5 buckets per minute, 5kg buckets at 8 buckets per minute, providing the optimal cost-effective solution for small and medium-sized production enterprises.

Mobile layout: The machine features a movable design without fixed pipelines, adapting to flexible adjustments in the workshop.

4. Wear-resistant and clog-proof hardware design

Large-diameter pipes: 3-inch flange interfaces reduce the risk of sand particle buildup and lower the probability of blockages.

Replaceable filling valve ports: Modular design for high-wear areas reduces maintenance costs by 40% compared to traditional equipment.

5. User-friendly human-machine collaboration

Manual speed adjustment knob for intuitive control of filling speed; new employees can be trained to operate the machine in 30 minutes.

Semi-automatic filling machine design balances efficiency and cost, achieving a 300% increase in speed compared to manual filling and a 40% reduction in investment compared to fully automated equipment.

6. Environmental and safety enhancements

Zero VOC leakage: Tankless design + sealed piping reduces solvent evaporation, compliant with OSHA workplace hazardous material control standards.

This equipment uses “sediment-free filling + intelligent precision control” as its core competitive advantage, precisely addressing the most challenging issues of layering and material loss for natural stone paint manufacturers. It is particularly suitable for small and medium-sized enterprises looking to upgrade production capacity while managing compliance risks.

IV. Summary

Due to its unique sand-like texture and decorative effect, the filling process for natural stone paint faces core challenges such as high viscosity, easy sedimentation, and high requirements for filling accuracy. SIGHTEC, as an excellent liquid filling machine supplier, builds efficient, stable, and clean stone paint filling production lines. This solution successfully addresses issues such as sedimentation and layering, insufficient filling accuracy, low efficiency, and environmental pollution, significantly improving product filling quality, production efficiency, and automation levels while reducing overall costs. It provides reliable technical support for large-scale, high-quality production of natural stone paint, driving the industry toward intelligent and green development.