Ⅰ.Unique Challenges in the Filling of Special Chemicals

1.1 What Are Special Chemicals?

Specialty chemicals refer to refined industrial products with specific functions, high added value, and relatively small production scales, such as electronic chemicals, pharmaceutical intermediates, high-performance additives, and specialty polymers. They typically have high purity, high activity, strong corrosiveness, or strict stability requirements, and are extremely sensitive to precision and safety in production, storage, and transportation.

1.2 Industry Pain Points in Special Chemicals Filling

High-risk medium characteristics: highly corrosive (e.g., hydrofluoric acid), highly toxic (cyanides), flammable and explosive (organic peroxides), and self-reactive (epoxy alkanes) substances. Even minor leaks or static sparks during filling can trigger major accidents.

Precision Requirements at the Limit: Filling errors for electronic-grade chemicals must be ≤±0.1%. Traditional equipment struggles to consistently meet this standard, and even minor deviations can lead to downstream product failure (e.g., a sharp drop in semiconductor yield).

High corrosion protection costs: Media such as hydrofluoric acid require equipment lined with Hastelloy C-276 or PTFE, with the cost of a single system exceeding that of a standard filling machine by more than five times, and maintenance costs skyrocketing.

Challenges of small batches and multiple varieties: The filling volume per batch often exceeds 200 liters, but switching between varieties requires 6–8 hours of cleaning and validation, resulting in equipment utilization rates below 50% and significantly increasing overall costs.

1.3 Selecting a specialized filling machine for filling is an essential requirement for the production of specialty chemicals

Precision control: Filling machines can achieve filling accuracy within ±0.5% using high-precision flow meters or weighing systems, thereby preventing waste of expensive materials;

Safety Assurance: Closed-loop filling systems isolate air (e.g., nitrogen-protected filling) to prevent reactions of flammable or oxidizable substances and effectively control the release of toxic vapors;

Contamination Prevention: Automated operations minimize human contact, preventing foreign particles from entering the system and meeting the cleanliness standards required for pharmaceutical-grade and electronic-grade products;

Process adaptability: Customizable corrosion-resistant materials (such as Hastelloy or PTFE coating) can be used to handle highly corrosive media, or low-shear filling modes can be designed to protect the structure of sensitive materials;

Compliance and efficiency: Integrated data traceability functionality ensures compliance with GMP, ISO, and other regulatory requirements, while enhancing batch processing efficiency and reducing overall costs.

Professional industrial filling machines are not only production tools but also core technological support for ensuring the quality, safety, and market competitiveness of specialty chemicals.

Ⅱ.What are the Methods of Liquid Filling?

The filling of hazardous chemicals is a high-risk operation, and the selection of filling methods must be based on a comprehensive consideration of factors such as the physical and chemical properties of the chemicals (e.g., flammability, toxicity, corrosiveness, volatility, viscosity, density), the specifications and materials of the packaging containers, filling accuracy requirements, production batch size, and most importantly, safety regulations. Inappropriate filling methods not only affect efficiency but may also lead to serious accidents such as leaks, fires, explosions, or poisoning.

The following sections provide a detailed explanation of several common filling methods used in the hazardous chemicals industry and their characteristics:

2.1 Manual Liquid Filling Machine:

Principle: Operators use simple tools to transfer and measure chemicals directly.

Features: Lowest equipment investment cost and high operational flexibility.

Advantages: Suitable for small-batch production, experimental filling, special packaging, non-standard containers, and scenarios with relatively low precision requirements.

Disadvantages: Low efficiency, high labor intensity, the highest risk of personnel exposure to hazardous chemical environments, filling accuracy significantly influenced by operator skill and condition, poor consistency. Prone to static electricity, leaks, splashes, and other issues, posing the greatest safety hazards.

Application Scenarios: Extremely small-scale operations, laboratory repackaging, sample preparation, emergency response, or special situations where automated equipment cannot be used.

2.2 Automatic Liquid Filler Machines:

Principle: Utilizes mechanical or electronic control systems (such as flow meters, load cells, liquid level sensors, and PLC program control) to automatically perform metering, filling, and valve opening/closing operations. Divided into automatic filling machines and semi automatic filling machine.

Features: High degree of automation and strong integration.

Advantages: Extremely high filling efficiency, particularly suitable for large-scale, continuous production. High filling accuracy and stable reliability with good repeatability. Significantly reduces direct contact between personnel and hazardous chemicals, greatly enhancing safety. Enables data recording and traceability, facilitating quality management. Can be integrated with cleaning, sealing, labeling, and other processes to form a production line.

Disadvantages: High initial equipment investment costs. Strict requirements for equipment maintenance and upkeep. When switching between chemicals or containers with different characteristics, parameter adjustments or component replacements may be required.

Application Scenarios: The mainstream filling method for various hazardous chemicals in large-scale industrial production, particularly suitable for flammable, explosive, highly toxic, highly volatile, or chemicals with strict precision requirements. Must be equipped with safety devices such as interlocks, leakage detection, emergency stop, and static elimination systems.

2.3 Gravity Flow Filling:

Principle: Utilizing the liquid’s own gravitational force, the height difference (potential difference) between the elevated storage tank (or mobile tank truck) and the receiving container is used to allow the liquid to flow naturally into the lower container. Flow is typically controlled via pipes and valves.

Features: Simple principle, low power consumption (primarily relying on potential energy).

Advantages: Relatively simple equipment, easy to operate and maintain. The filling process is relatively smooth, with lower risks of static electricity and turbulence.

Disadvantages: Filling speed is limited by the height difference and material viscosity, typically resulting in slower filling rates. Sufficient vertical space is required to establish an effective height difference. Filling accuracy control is less precise than automatic filling systems with metering devices (often requiring liquid level observation or overflow ports).

Applications: Filling of viscous liquids or materials sensitive to pressure or mechanical agitation. Commonly used for drum filling (IBC ton drums, 200L steel drums) or tank truck filling.

2.4 Pressure Filling:

Principle: Utilizes externally applied pressure (typically compressed air, inert gases such as nitrogen, or pumped pressure) to “force” chemicals from a storage tank into the target container. The pressure source overcomes pipeline resistance and container backpressure to drive fluid flow.

Features: Fast filling speed and high efficiency.

Advantages: Fast speed, high efficiency, suitable for large-scale filling. Can overcome significant pipeline resistance or long-distance transportation. Applicable to liquids with a wide viscosity range (from medium-low viscosity to certain high viscosities). Enables sealed filling, reducing material evaporation and personnel exposure.

Disadvantages: The equipment system is relatively complex (requiring a pressure source, pressure regulating valve, safety valve, etc.), resulting in higher costs. Improper pressure control may lead to overpressure, damaging containers or pipelines and causing hazardous leaks.

Application scenarios: High-volume operations requiring rapid filling; low-viscosity, easily flowing chemicals; flammable liquids (must use inert gas pressurization); materials requiring isolation from air/oxygen during filling.

Ⅲ. Sightec Specialty Chemicals Filling Solutions

3.1 Basic Configuration of Large Drum Liquid Filling Line

1. Automatic Labeling Machine

Explosion-proof thermal transfer labeling machine, labels resistant to chemical corrosion (acid/solvent resistant), positioning accuracy ±0.5mm.

2. Automatic Palletizing Machine

ATEX-certified explosion-proof robotic arm capable of handling mixed codes of IBC drums and steel drums, with collision sensors featuring sensitivity of ±2 mm.

3. Automatic Explosion-Proof Filling Machine

Intrinsically safe explosion-proof sensors: circuit energy is limited to the microjoule level, preventing ignition of explosives even in case of short circuits or open circuits. Explosion-proof cable entry devices (with rubber seals and metal armor).

Explosion-proof solenoid valve: Coil operating temperature is controlled below 85°C (T6 class), while ordinary valves can reach over 120°C during frequent operations, potentially igniting flammable gases.

Explosion-proof electrical control box: Made of thickened steel plates/cast aluminum with precision-machined flange joint surfaces. The high-strength sealed housing confines any internal sparks or explosions within the box, while precision structural gaps cool the flames and block explosion propagation.

Explosion-proof motor: In the event of an internal short-circuit explosion, flames are vented through long joint surface gaps, with temperatures reduced below the ignition point, preventing ignition of external gases.

4. Automatic lid dispenser

Magnetic lid separation + visual positioning, suitable for metal/plastic inner lids

5. Automatic drum dispenser

Variable frequency control of drum spacing, corrosion-resistant 304 stainless steel chain, drum positioning error ≤ ±1 cm (Ensures precise alignment of the filling nozzle)

6. Automatic capping machine

Torque closed-loop control (adjustable from 20 to 150 N·m), integrated capping seal integrity testing

7. Automatic checkweighing and rejection machine

Explosion-proof high-precision weighing (resolution 1 g), automatic rejection of out-of-spec products + data traceability

8. Empty drum conveyor line

Z-shaped incline conveying design, equipped with a residual liquid detection probe at the bottom of the drum (alarm triggers when residual volume exceeds 5mL)

9. Line change conveyor

Modular quick-change interface, compatible with 200L steel drums/plastic drums/IBC drums, changeover time ≤15 minutes

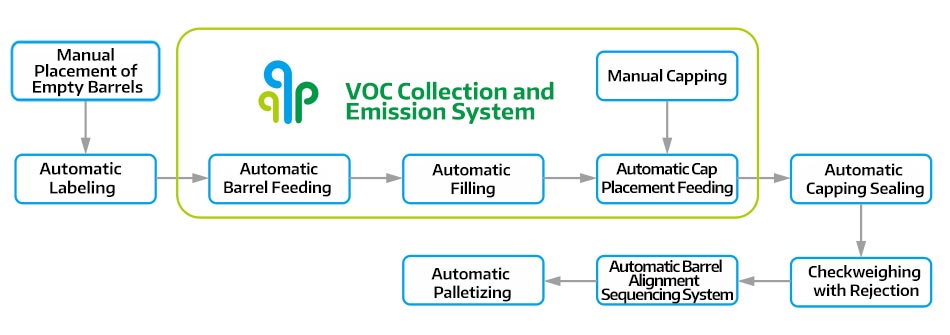

10. VOC collection and exhaust system

Two-stage treatment with condensation and activated carbon adsorption, emission concentration <10mg/m³

3.2. Advantages of the Sightec Filling Production Line

1. Automatic execution modules: automatic empty bucket feeding, automatic labeling, automatic bucket feeding, automatic filling, automatic lid placement, automatic lid sealing, automatic weight checking and rejection, automatic bucket removal, and automatic palletizing.

2 . Suitable for open-top bucket weighing and filling, utilizing SIGHTEC dual-head filling technology to ensure stable production output.

3. Dynamic Flow Compensation: Two-stage filling control + automatic weight correction for precise compensation of material drop differences.

4 . Stepped Conveying Method: Modular conveying design ensures synchronized line rhythm, with operational efficiency reaching 99.2%.

5 . Equipped with a VOC collection exhaust hood covering the filling, lid placement, and capping stations.

6 . Features a bucket blocking mechanism with finished bucket separation and sequential lid placement and capping functions, with lid placement and capping speeds matched to packaging speed.

7 . Automatic labeling function enables side labeling of containers. Multiple label holder sizes accommodate various label dimensions, offering greater flexibility for adjustments when label sizes or product specifications change.

8. Each finished container undergoes precise weight detection, with automatic alerts and rejection for containers failing to meet weight requirements.

9 . The palletizer uses automated robotic arms for precise palletizing operations, reducing labor costs and error rates.

Ⅳ.SIGHTEC is dedicated to the research and development of industrial filling machines.

Our semi-automatic tabletop filling machines, automated filling machines, inline filling machines, and chemical filling equipment can handle a wide range of chemicals, including adhesives, additives, antioxidants, corrosive products, dyes, and many other sensitive liquid products. With breakthrough advancements, our equipment delivers precise and repeatable filling using servo-driven technology, featuring turret-mounted labeling, weight compensation functionality, and user-friendly touchscreen operation.

Our reliable liquid filling equipment is customizable to meet your evolving needs, designed to deliver high performance and low total cost of ownership year after year.

Contact us today to learn more about our liquid filling and packaging solutions tailored for your chemical specialty applications.

Contact SIGHTEC:

Tel: +86 181 3719 7160

Web: www.sightec.net

Email: info@sightec.net

WhatsApp Available