SIGHTEC’s Innovative Solutions:

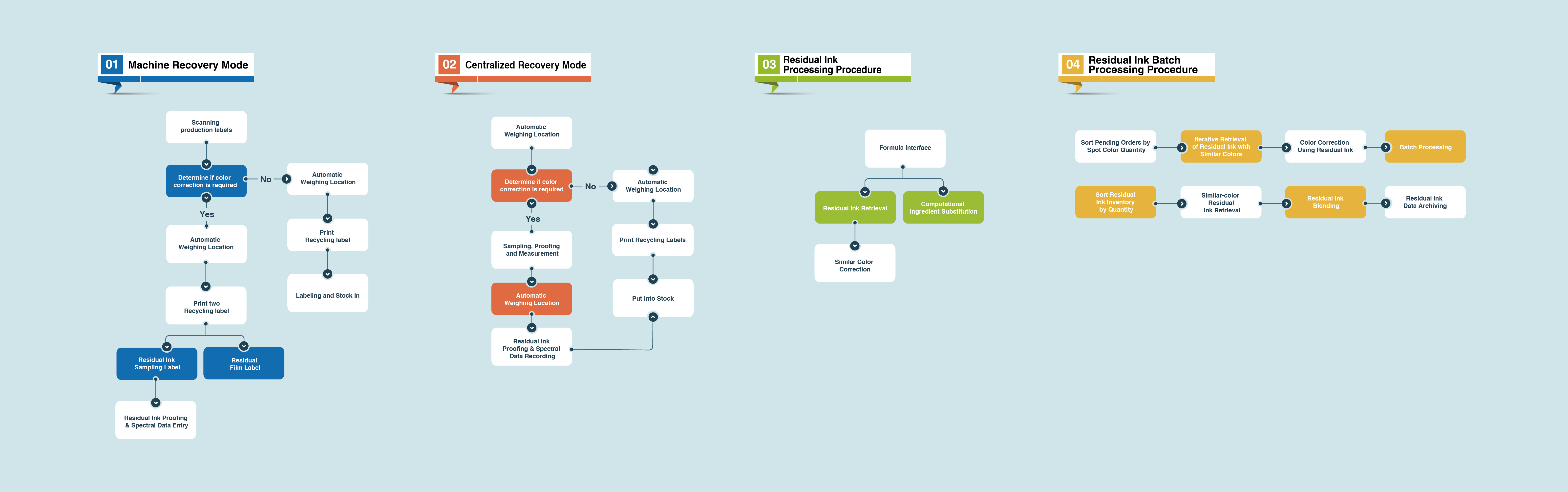

SIGHTEC addresses this critical issue with two advanced residual ink handling methodologies:

Ⅰ.Computational Recycling

Process of Computational Recycling:

1. Calculates and compares the ingredients of the residual ink formula and the required ink formula.

2. Race the batch in the residual ink bank and race out the residual ink that can be used.

3. The system then calculates the precise amount of additional ink components needed to blend the residual ink into the target formula.

Advantage of Computational Recycling: Streamlined and time-efficient processing

Disadvantage of Computational Recycling:

Cannot utilize residual ink batches that are a similar color but have a mismatched formula, potentially leaving usable material unprocessed.

Ⅱ.Spectral Matching & Color Correction (Overcoming Computational Limitations)

Process of Spectral Matching & Color Correction:

1. Database Creation: The full spectral data (reflecting the color characteristics) of all residual ink batches is stored in the inventory database.

2 . Target Measurement: A spectrophotometer measures the spectral data of the required target color.

3. Spectral Matching: The system performs a batch search within the residual ink inventory, finding all batches closest in spectral match to the target color – regardless of their original formula.

4 . Automated Correction: SIGHTEC’s color matching software automatically performs color correction calculations on the selected residual ink batches to achieve the precise target color.

Advantage of Spectral Matching & Color Correction:

This process enables the efficient and automated reuse of a much wider range of residual inks, including those with similar colors but different formulas.