In modern coating production, the precise proportioning of liquid raw materials such as resin, solvent and additives directly critically determines core coating properties like adhesion strength, weather resistance, and gloss level.

However, reliance on traditional manual dosing methods presents significant challenges. These experience-dependent processes often lead to 3 critical pain points:

1.Insufficient precision: the weighing error is generally ±3%-5%, and the deviation of trace additives (e.g. curing agent) can easily lead to batch quality fluctuations.

2.Inefficiency: manual handling, checking, and recording take up more than 30% of the production cycle.

3.Data Black Holes: relying on paper records, data is difficult to trace, easy to tamper with, and does not meet ISO quality management requirements.

Liquid batching system through multi-sensor synergistic metering, PLC intelligent control architecture, to improve the accuracy to ± 0.1%-1%, for coatings, inks, adhesives and other industries to provide industrial-grade solutions.

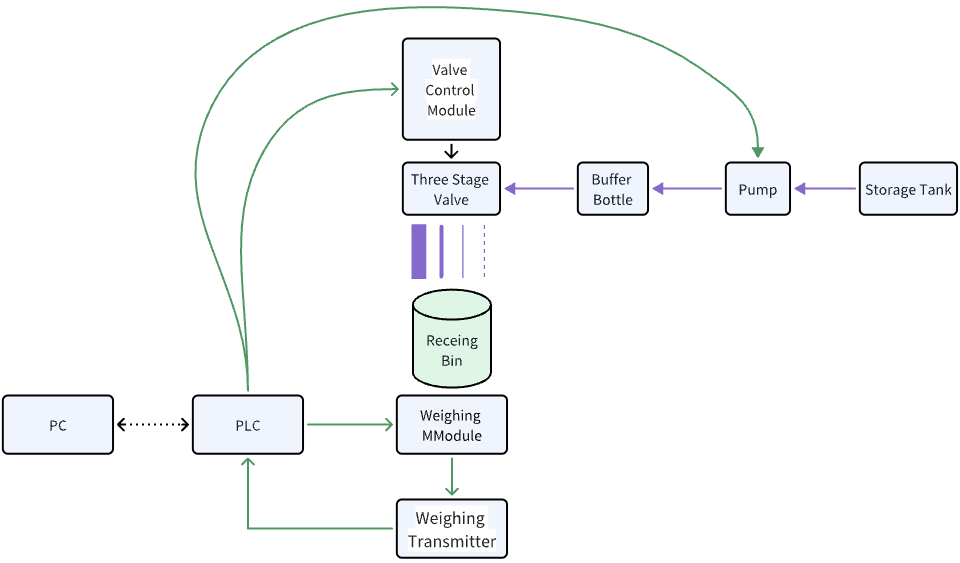

The liquid batching system adopts the layered architecture of “perception-decision-execution” to realize the control of the whole process:

1.Perception layer:

High-precision load cell (static compensation module) real-time monitoring of the material gravity changes, eliminating bubbles, density fluctuations on the flow meter interference.

Level meter, pressure sensor linkage, to prevent overflow, and hold pump in case of an accident.

2.Decision-making layer:

PLC performs weight proportional feed-forward + fuzzy self-tuning PID algorithm, dynamically adjusting the valve opening and pump opening and closing.

formula encrypted management + three-level authority control (operator/engineer/administrator), to protect process safety.

3.Execution layer:

Third-order valve group to realize flow hierarchical control:

|

Value Type |

Flow range |

Function Stage |

|

High Speed Valves |

>20~60L/min |

High Flow Fill 90% |

|

Medium Speed Valves |

10L/min |

Transition Adjustment |

|

Micro Valves |

<1L/min |

Avoid Add Over |

|

Drip Addition |

0.1~4g/drop (system automatic adjustment) |

Precision Adjustment (±0.1g error) |

1.Intelligent Formula Management:

After the operator selects the formula, the liquid batching system automatically calculates the amount of each material added, linkage pumps, and valves to complete the feeding and valve cleaning.

Supports 10,000+ formula storage, 1-click switching to adapt to the production of multiple varieties.

2.Dynamic error-proof design:

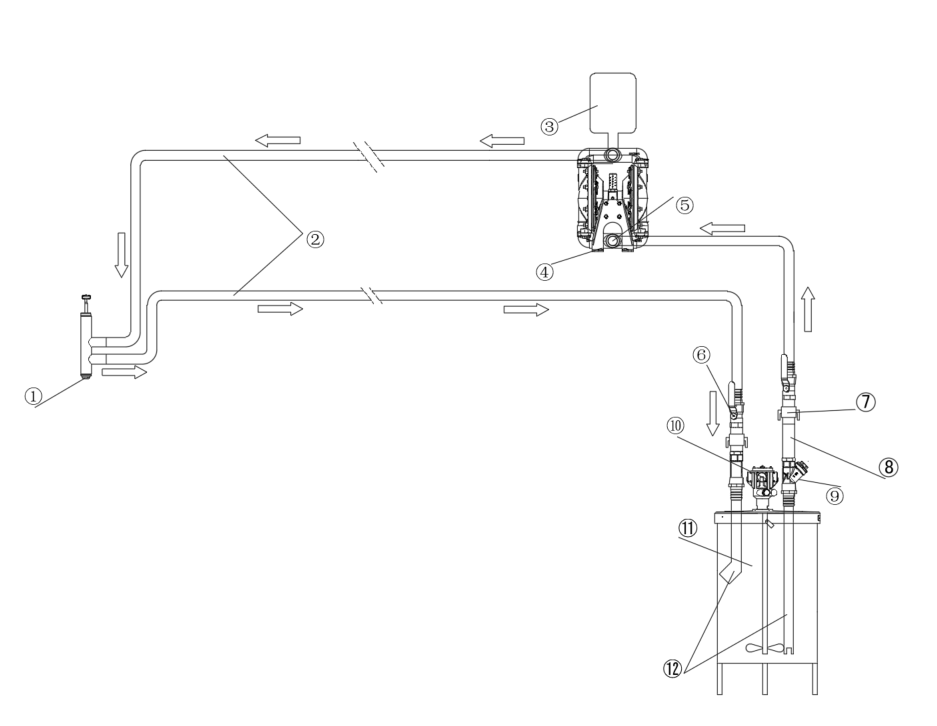

Raw material batch and inventory management module: low-level automatic prompts, low-level alarm, trigger replenishment reminder.

Tank timer stirring and pipeline reflux function: to prevent stratification, sedimentation, and caking.

3.Full life cycle data traceability:

Production data (actual feeding quantity, raw material batch, operator, time stamp) are automatically stored in SQL database, supporting the generation of reports in line with ISO standards.

|

Manual Dosing |

Automated Batching System |

|

|

Accuracy |

±3-5% |

±0.1%-1% (Closed-loop) |

|

Speed |

Multi-handling cycles |

60 kg/min continuous flow |

|

Data Integrity |

Paper-based (loss/error) |

SQL + Auto-Backup |

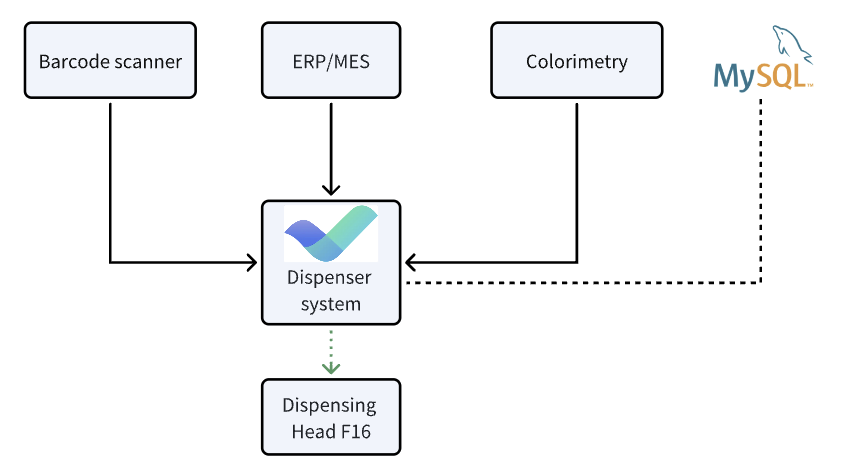

The batching system has been successfully applied to:

-Paint industry: accurate proportioning of resin base and color paste;

-Printing color mixing: with the color measurement and matching system to quickly complete the task of ink matching, on-demand production.

Conclusion: Reshaping the production triangle with “intelligent control.”

Automated Liquid Batching Systems reconstruct industrial efficiency through:

Closed-Loop Metrology (Static load cell + Flow calibration)

3-Stage Flow Grading (High-Medium-Micro valve architecture)

Digital Twin Traceability (Recipe-to-batch data chain)

This transforms coating production from “experience-dependent art” into a data-driven science – where precision, throughput, and compliance become non-negotiable standards.