In the industrial manufacturing sector, color consistency is one of the key indicators for assessing product quality. However, across industries such as printing, coatings, automotive, and textiles, companies have long faced challenges such as color deviations in products, low labor efficiency, and high production costs. These issues have become the core obstacles hindering corporate progress.As a dispensing machine manufacturers, Sightec understands that solving industry issues is a matter of urgency. Through continuous testing and research on color matching engineering in the industrial sector, Sightec has developed a comprehensive color matching system solution represented by the D2-INK ink mixing system, which is emerging as a key tool for addressing color management challenges in the industrial sector. This article will focus on how the INK Dispenser system addresses industry pain points and highlights its product advantages.

Ⅰ.Core challenges facing color management in the industrial sector: the dilemma of digital transformation

Printing industry: a disconnect between technology and efficiency.

Small and medium-sized printing companies generally rely on experienced technicians for manual color calibration, which is inefficient and makes it difficult to ensure color consistency between batches. Due to the lack of automated equipment, frequent adjustments result in significant waste of raw materials and loss of production efficiency.

Coatings and Automotive Manufacturing: Bottlenecks in Precise Color Control.

Color matching for vehicle body coatings and interior components is critical to brand image. For automotive brands, color consistency is a necessary production condition. However, manual color adjustment processes struggle to precisely replicate standard color swatches, leading to noticeable color differences between production batches, which directly impact product appearance quality and consumer perception.

Food and Packaging: Challenges in Visual Appeal and Quality Control.

The color of the product itself and the printing quality of its packaging are key sensory factors influencing purchasing decisions. However, issues such as natural color fluctuations in raw materials and color deviations during packaging printing processes are difficult to quantify and control through subjective visual assessments effectively.

Textile Dyeing: Light Source Dependency and Commercial Risks.

The textile industry is severely affected by the “metamerism” effect, where fabrics exhibit significant color differences under different light sources (commonly known as “light jumping”). This phenomenon leads to color mismatches during customer inspections, significantly increasing the risk of returns and claims.

Ⅱ.The Bottom Line Color adjustment system solutions: Accurately solving industry challenges

2.1 Core Advantages of the Automatic Paint Tinting System for Coatings Production Lines

Ensuring Color Consistency Between Batches:

Through precise verification of professional formulas, the system accurately reproduces formulas to ensure high color consistency between different batches of products. This not only meets customers’ stringent requirements for long-term color stability of products, but also safeguards brand reputation and end-user experience.

Optimizing Production Process Efficiency:

Automated color matching replaces manual operations, enabling the system to quickly and accurately complete color matching tasks. This significantly reduces batch changeover time, accelerates production cycles, and comprehensively enhances production line throughput and overall operational efficiency.

Enhancing product quality reliability:

Through high-precision metering pumps, sensors, and closed-loop control systems, the system minimizes variables and errors introduced by human intervention. This ensures the quality stability and predictability of finished coatings.

Achieving end-to-end cost optimization:

1.Direct savings: Precise raw material dispensing significantly reduces waste of expensive pigments.

2.Hidden cost savings: Fundamentally reduces costs associated with customer returns, rework, and related logistics and warehousing losses caused by color mismatches.

3.Efficiency gains: Reduces downtime for color matching, frees up production capacity, and lowers unit costs.

Practicing sustainable production principles:

Precise batching significantly reduces resource consumption and waste emissions, demonstrating environmental benefits and aligning with increasingly stringent environmental regulations and sustainable manufacturing trends.

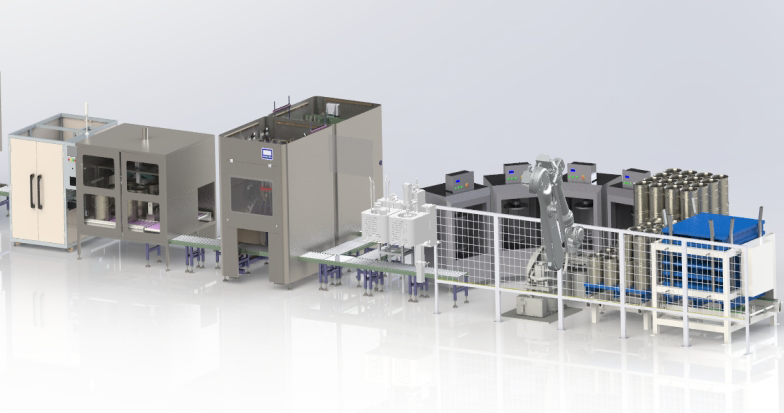

2.2 Basic configuration of D2-Ink Automatic Paint mixing Machine

1.Spectrophotometer

Spectrophotometers enable rapid retrieval and efficient management of ink formulations by accurately measuring the spectral data of standard samples, significantly optimizing the ink recycling (reuse) process.

In addition to density and color measurement, it supports all printing standards, including G7, ISO, PSO, and JapanColor. Furthermore, the accompanying BestMatch function guides users in adjusting the ink blackness of the printing press to more accurately match specific color standards.

2.Gravure Printing Ink Proofer

The Gravure Printing Ink Proofer is a critical pre-press tool used to verify the accuracy of both newly developed and existing ink formulas. It simulates production press conditions to assess key properties like color match, density, adhesion, and drying, ensuring the ink performs as expected before committing to full-scale printing runs.

3.Color Matching Software

Color matching software combined with industrial dispensing equipment. It can quickly input raw ink residue data into the system while simultaneously performing data management, enabling rapid and accurate retrieval of potential ink residues during the production process. Color matching software calculates the formula ratios for new or old inks, automatically optimizes the formula, and reduces manual intervention. The software is not only applicable to the ink industry but can also be extended to industries such as coatings, textiles, and plastics.

4.Paint Tinting Equipment

The paint tinting machine significantly improves the efficiency and reliability of formula verification. It automatically and accurately extracts and mixes color pastes according to the precise proportions provided by the software, quickly producing actual color samples. This process completely replaces the traditional cumbersome steps of manual weighing and mixing by technicians, not only greatly improving speed but also eliminating the risk of human error, ensuring the rapid and reliable implementation of software formulas.

2.3.Technical advantages of D2 ink compared to other automatic paint mixing machines

1. Perfect Matches, Guaranteed

Stop the guesswork forever. Industry-leading devices like the D2-INK digital dispensing system integrate built-in spectrophotometers for scientific color measurement. They scan color standards with lab-grade precision, instantly retrieve optimized formulas from cloud databases, and dispense spot-color inks with 0.02ml accuracy. Achieve first-pass match success every time – eliminate customer rejects and costly rework.

2. Stop Wasting Money

Stop pouring profits down the drain. Manual mixing wastes up to 15% of expensive pantone inks or automotive coatings. The D2-INK automatic paint tinting machine calculates exact material requirements, reducing ink waste by dosing pigments down to the milliliter. Direct savings on raw material consumption protect your bottom line – reclaim thousands in annual overspend.

3. Accelerate Production Workflows

Transform mixing from hours to seconds. Need a custom color formula? The automated dispensing technology delivers real-time formula access and dispenses at high-speed 0.25L/min flow rates. Technicians shift from manual paint mixing to value-added tasks – shorten job turnaround by 70% and unlock production line efficiency. Faster batches = higher throughput = increased revenue.

4. Uncompromising Batch-to-Batch Consistency

Eliminate color variance nightmares. Whether matching automotive touch-up paint or executing large-format printing runs, the D2-INK digital liquid dispenser replicates complex formulations with machine precision. Achieve identical hue/saturation/luminance across every batch. Build customer trust with flawless color reproduction – from prototype to mass production.

5. Handle Complexity Effortlessly

Conquer advanced chemistry challenges. Modern metallic coatings, UV-curable inks, and water-based colorants demand scientific control. The modular ink dispensing system handles 16 canisters configurations for multi-component blending, seamlessly managing solvent-based, aqueous, and hybrid formulations. Simplify specialty color creation while maintaining viscosity control and material compatibility. Modern colors and inks are tough. The D2-INK handles 16 canisters and works with solvent-based inks (and water-based colorants). It takes the stress out of complex multi-component formulas.

2.4. Application Cases: Full-chain Value Realization from Laboratory R&D to Factory Production

1. Packaging Printing: Overcoming Color Difference Difficulties in Highly Reflective Substrates

As a professional auto paint tinting machine, D2-Ink can be adapted to various printing processes such as offset printing, flexographic printing, gravure printing, and screen printing, as well as different substrates such as paper, plastic film, and metal foil. Whether the application is for precision labels, large-format posters, or packaging materials with special textures, it can achieve high-precision color measurement. The adjustable measurement aperture and optional lighting source design ensure high flexibility in meeting various printing measurement requirements, providing printing companies with a comprehensive color management solution.

2.Label Printing: Accurate Reproduction of International Standard Spot Colors

Direct, precise ink supply without transmission errors, one-click printing, colors meet international standards, addressing the root causes of traditional ink supply issues such as inaccurate ink dispensing and unstable color control. D2-INK automotive paint tinting machine is applied in the UV label printing field, featuring precise ink volume calculation and real-time dynamic ink supply without manual color calibration. It delivers accurate colors, richer details, and a more vibrant, saturated printing image.

3.Coatings industry: Cloud-based empowerment for agile R&D and production

The automatic color matching system enables precise formula production, achieving on-demand production and reducing ink waste. It also ensures accurate manual feeding, minimizing raw material waste caused by manual color matching by machine operators, bringing revolutionary changes to the coatings industry. Through accurate color control and efficient production processes, coatings companies can provide higher-quality products to meet market demand while achieving cost savings and environmental friendliness.

Ⅲ.Key Challenges in the Deployment and Operation of Automated Color Matching Equipment

1. Adaptability Pressure from Technological Iteration

The coatings industry is undergoing continuous technological evolution (such as water-based coatings, high solids content, and the application of new functional pigments/additives), with new formulations and stricter color standards (such as updates to international automotive color standards) emerging constantly. This necessitates regular software and hardware upgrades for automated color matching systems to ensure their algorithm libraries, color matching models, and driving capabilities can effectively accommodate and accurately process these innovative elements. Failure to do so risks technological obsolescence.

2. Complexity and Necessity of Maintenance and Calibration

The system’s high precision relies on the long-term stability and condition of critical components (such as high-precision metering pumps, tubing, and sensors). This necessitates the establishment and strict enforcement of periodic professional maintenance plans (including cleaning, inspection/replacement of critical components) and precise calibration processes to counteract performance drift caused by equipment wear, environmental changes (temperature, humidity), and the accumulation of pigment residue, thereby ensuring the long-term reliability of measurement and color matching. Neglecting maintenance will directly result in reduced accuracy and wasted costs.

3. Significant Initial Capital Expenditure Threshold

Achieving the core value of automated color matching (precision, efficiency, consistency) requires investment in high-performance color matching machines,supporting software, integrated control systems, and potential facility renovations. This substantial initial investment (CAPEX) constitutes a significant financial decision threshold for many companies, especially small and medium-sized paint manufacturers, necessitating detailed return on investment (ROI) analysis and financial planning.

Ⅳ.Conclusion

With the continuous advancement of coating technology, automatic color matching systems need to be upgraded regularly to adapt to new coating formulations and color standards. As a auto paint tinting machine manufacturer, Sightec is committed to providing higher quality products to meet market demand while achieving cost savings and environmental friendliness. Faced with challenges such as technological updates and equipment maintenance, coating companies need to continuously optimize their automatic color matching systems to maintain their competitiveness in the market.

Contact SIGHTEC:

Tel: +86 181 3719 7160

Web: www.sightec.net

Email: info@sightec.net

WhatsApp Available