1. Revealing The Core Value Of Modern Coating Equipment Through Industry Pain Points

1. 1. Paint Mixing Industry Pain Points

Still struggling with manually mixing coatings? After spending hours mixing, you still find stubborn lumps at the bottom of the can and annoying color differences on the paint surface? Not only is this time-consuming and labor-intensive, but it also results in low efficiency. More seriously, uneven coating mixing can directly ruin your professional coating effect. Pigment settling and inconsistent viscosity result in compromised gloss, adhesion, and durability of the final coating.

1.2.Core Value Preview: A Revolutionary Solution for Modern Paint Mixing Equipment

Say goodbye to inefficiency and uncertainty! This article will delve into how modern paint mixing equipment (Painting Mixer) can become the efficiency and quality engine of your workshop. Learn how they:

Ultra-fast mixing: Significantly reduces the time of color mixing in paint, boosting work efficiency by up to 90%, giving your production process a competitive edge.

Precise uniformity: Eliminate lumps and color discrepancies, ensuring every drop of paint is perfectly homogeneous, laying the foundation for the ultimate stability and excellence of coating quality.

Significantly reduce waste: Minimize paint waste, avoid scrap caused by uneven mixing, and directly reduce costs.

Process reliability: Enhance consistency between batches to ensure every coating application meets predictable professional standards and consistently enhances customer satisfaction.

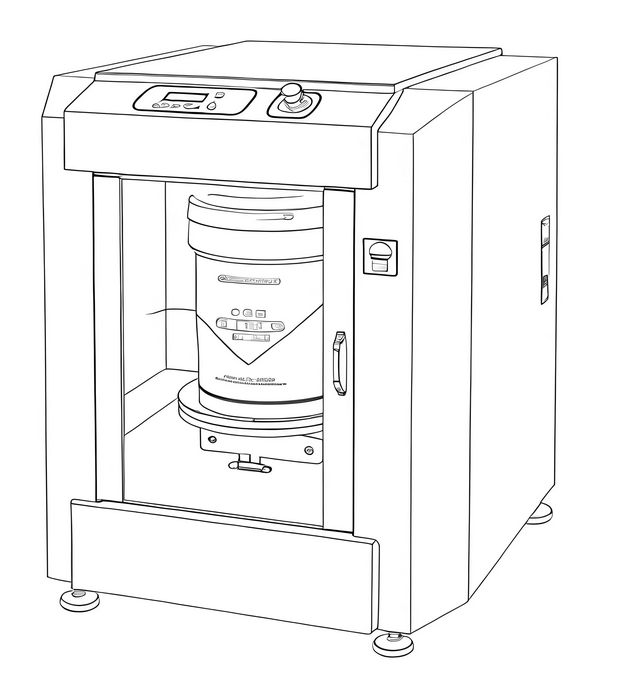

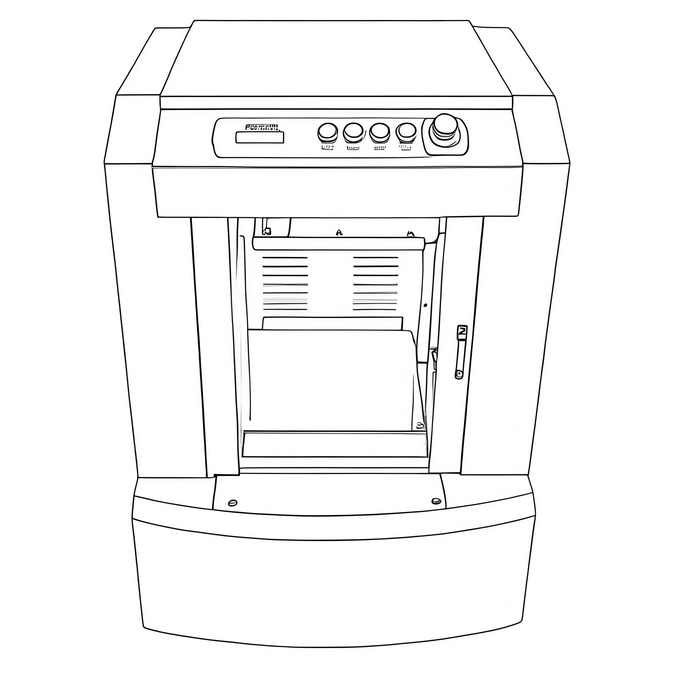

This article will use two products—the automatic rotating mixer and the automatic oscillating mixer—to detail how automated equipment addresses these issues, helping you save time, reduce waste, and enhance process consistency.

Ⅱ. Why choose an automatic paint mixing machine?

1. Mixing uniformity is more stable, eliminating batch differences

The uniformity of a coating directly determines its final properties (such as hiding power, adhesion, weather resistance, etc.). Manual mixing relies on manual experience, and it is difficult to accurately control the intensity, frequency, and time. During manual mixing, pigment particles are easy to settle at the bottom of the container and are difficult to completely disperse, resulting in excessive local concentration. The automatic mixer can achieve standardized mixing through preset parameters (such as speed, time, and mixing trajectory). The mixing effect of the same batch or different batches of paint is highly consistent, reducing quality fluctuations from the source.

2. Improve efficiency and adapt to large-scale production

Coating production (especially industrial coatings and batch civil coatings) requires high-frequency and large-batch mixing. It may take 10-15 minutes to manually mix a barrel of 20L coatings, and only 1-2 barrels can be processed at a time, which is difficult to meet the production line rhythm; The automatic mixer can realize continuous and batch operation: it can process multiple barrels (such as 6-12 barrels) at a time, the mixing time is shortened to 3-5 minutes, and the efficiency is increased by 5-10 times;

SIGHTEC paint mixer supports linkage with production lines, such as automatic loading and unloading, reducing manual transfer time and adapting to industrial assembly lines.

3. Reduce labor costs and labor intensity and improve safety

The paint contains harmful substances such as solvents and heavy metal pigments, and there are multiple problems in manual mixing:

Manual stirring requires close contact with materials, which can easily cause health risks due to volatile inhalation or skin contact;

Manual mixing of high-viscosity coatings is labor-intensive, and long-term operation can easily lead to occupational injuries.

Through closed mixing and mechanical drive, the color mixer machine can:

Reduce direct contact between labor and materials and reduce health risks;

Replace manual heavy physical labor and improve operation safety and comfort.

4. Data can be traceable to meet quality control requirements

Modern coating production has strict requirements for quality traceability. The parameters of manual mixing (such as basic colour mixing time and strength) are difficult to record, and the cause cannot be quickly traced when quality problems occur.

The stainless steel paint mixer has data recording function:

It can automatically store parameters such as mixing time, rotation speed, and material information of each batch to form a traceable quality file.

5. Adapt to complex coating systems and expand application scenarios

Some special coatings require extremely high mixing precision, and it is difficult to achieve dispersion effect by manual mixing

Automotive paint mixing equipment can meet the mixing needs of complex systems through customized design and help enterprises expand the production capacity of high value-added products.

Ⅲ.The Difference Between the Automatic Shaker and the Automatic Mixer

Core Differences Overview:

The core objective of both devices is to achieve uniform mixing, dispersion, or prevention of settling of coatings (including color pastes, resins, additives, pigments, etc.). However, the physical mechanisms they employ to achieve this objective are fundamentally different, resulting in significant differences in their applicable scenarios.

1. Machine Principle

Automatic Mixer:

Principle: Based on three-dimensional rolling motion. The sample container (typically a bottle or jar) is secured to a rotating fixture. The fixture drives the container to perform composite rotational motion around one or more axes (commonly three-dimensional eccentric rotation or “planetary” rotation).

Physical Action: Primarily relies on the combined effects of gravity, centrifugal force, and inertial force. The material inside the container is continuously lifted, flipped, slid, collided, and compressed during the motion. This motion creates complex vortices and shear forces within the container, but it primarily involves overall movement at the macro level rather than intense local shear.

Objective: To achieve uniform distribution of material across all areas within the container, particularly effective at addressing layering (sedimentation) caused by density differences and macro-level uniformity issues. The mixing process is relatively gentle.

Automatic Shaker:

Principle: Based on high-speed linear reciprocating motion (oscillation or orbital oscillation). The sample platform (fixed sample container) performs rapid linear reciprocating motion or small circular motion (orbital oscillation) within the horizontal plane.

Physical action: Primarily relies on intense inertial shear forces. When the platform moves back and forth at high speed, the material inside the container lags behind the movement of the container walls due to inertia, resulting in strong velocity gradients (shear layers) within the material. This causes intense friction and collisions between material particles and between the material and container walls. Orbital oscillation also adds a slight centrifugal effect.

Objective: To achieve rapid, powerful mixing, dispersion, homogenization, and resuspension. It is particularly effective at breaking agglomerates, dispersing particles, mixing high-viscosity materials, and rapidly homogenizing. It offers high mixing intensity.

2. Working Mode

Automatic Rotating Mixer:

Motion Trajectory: Rotation and revolution go simultaneously.

Speed: Relatively low rotational speed . The motion appears more “gentle.”

Container Requirements: Containers typically need to be symmetrical, well-sealed (especially for liquids), and must be balanced, otherwise the machine may vibrate violently or even be damaged. Fixture designs vary to accommodate containers of different shapes and sizes

Process Observation: The mixing process is relatively easy to observe.

Noise Level: Typically low .

Sample state: The material inside the container moves as a whole, forming “waves” or “vortices.”

Automatic Shaker:

Motion Trajectory: Quickly and thoroughly mix by high speed vibration.

Speed: Extremely high oscillation frequency (typically within the range of 300–3000 RPM or OPM). The motion appears very intense and rapid.

Container Requirements: Minimal restrictions on container shape (round-bottomed, conical, square bottles, etc. are all acceptable), no strict symmetry or balance required . Containers are typically secured using clamps, springs, or foam pads. Extremely high sealing requirements , otherwise splashing may occur.

Process Observation: During high-speed oscillation, the container and contents move too quickly to clearly observe the internal mixing state.

Noise: Typically high

Sample State: The material inside the container undergoes intense shear, with the central region lagging behind the edges and bottom, creating strong internal flow and shear layers.

3. Suitable Coating Viscosity

Automatic Paint Mixer:

Optimal Range: Best results for low to medium viscosity coatings.

Medium Viscosity: Can be processed, but efficiency decreases. Material flowability weakens, and tumbling mixing effectiveness deteriorates.

High Viscosity/Paste-like: Poor results or ineffective.

Application Scenarios: Preventing pigment settling, mixing low-viscosity resins and additives, pre-mixing color paste with base paint after color matching, and homogenizing after storage.

Automatic Paint Shaker:

Advantageous Range: Excellent performance for medium to extremely high viscosity/paste-like coatings,color mixing painting,mixing automotive paint.

Principle Advantage: Intense shear force effectively overcomes resistance caused by high viscosity, forcibly pulling, folding, and compressing the material to achieve powerful mixing and dispersion. Even with viscous materials, inertial shear continues to act within the material.

Low viscosity: Can be processed, but may be overly vigorous, prone to bubble formation, and may not be the most economical choice for low-viscosity coatings requiring only gentle mixing to prevent settling. Additionally, high-speed oscillation requires stringent liquid sealing requirements.

Application scenarios: Dispersing pigment agglomerates, mixing high-viscosity components, homogenizing paste-like products, rapidly resuspending severely settled color pastes, and achieving strong dispersion in laboratory small-scale samples.

4. User Needs

Requirements Met by Automatic Rotary Mixer:

Gentle, non-destructive mixing: Requires maintaining the original structure of the coating, avoiding the introduction of excessive bubbles or damage to sensitive components.

Preventing layering/settling: Efficiently and gently re-homogenizing minor layering or settling that occurs in low to medium viscosity coatings after long-term storage.

Macroscopic uniformity: Ensures that the paint components and color are macroscopically consistent across different locations within the container.

Simultaneous processing of multiple containers: Typically features multiple workstations, enabling simultaneous processing of multiple sample bottles or small cans, offering high efficiency and suitability for color matching, quality control sampling re-testing, and small-batch production.

Low noise: Suitable for laboratories or workplaces requiring a quiet environment.

User-friendly operation: Loading, program setup, and operation are relatively simple and intuitive.

Safety: Container sealing requirements are relatively easy to meet, and movement is relatively smooth.

Applications Met by the Automatic Platform Shaker:

Powerful mixing and dispersion: Requires rapid, powerful mixing of incompatible components, dispersion of hard agglomerated pigments or fillers, and homogenization of high-viscosity systems.

Processing high-viscosity materials: One of the primary mixing methods for handling difficult-to-flow materials such as pastes, putty, and high-solids coatings.

Rapid homogenization/resuspension: For materials prone to severe settling or layering, it can achieve rapid resuspension and homogenization.

Efficient processing of small-volume samples: In laboratory R&D and small-scale sample preparation, it achieves extremely high efficiency in strongly dispersing and mixing small quantities of high-viscosity samples.

Breaking agglomerates: It has a good redispersing effect on soft agglomerates formed after pre-dispersion or during storage.

Flexible container compatibility: It has low requirements for container shape, making it convenient to use with various existing containers.

Ⅳ.Conclusion

For the car paint mixing equipment, rotary mixers and oscillating mixers are not substitutes for each other but complementary, serving different process stages and material characteristics:

Choose a rotary mixer: When your primary requirement is to gently mix low to medium viscosity coatings, prevent or eliminate sedimentation and layering, achieve macro-level uniformity, process multiple samples simultaneously, and the material viscosity is not particularly high.

Choose an oscillating mixer: When your primary challenges include mixing high-viscosity or paste-like coatings, requiring strong dispersion of pigment/filler agglomerates, rapidly homogenizing systems prone to layering, and processing small volumes of difficult-to-mix samples.

Many modern paint laboratories, paint production lines and mixing machines for paint are equipped with both types of equipment to select the most appropriate mixing tool based on the specific material state (viscosity, settling, agglomeration) and process requirements, thereby achieving optimal results and efficiency.

Contact SIGHTEC:

Tel: +86 181 3719 7160

Web: www.sightec.net

Email: info@sightec.net

WhatsApp Available