Our comprehensive laboratory systems ensure the highest accuracy in ink formulation from the outset, enabling the efficient reuse of residual inks.

Laboratory Equipment List:

1.High-Precision Dispenser (Accuracy: 0.039ml):Used for precise addition of ink components in small quantities.

2.Flexo/Gravure Ink Proofer:Simulate printing conditions to achieve accurate color evaluation.

3.Color Measurement Instrument (Spectrophotometer):Provides objective, digital color data.

4.Automatic Color Matching Software:he intelligence behind rapid, accurate formula creation and optimization.

5.Standard Light Source (for color matching):Ensures consistent color evaluation under controlled lighting

6.Viscosity Cup:An essential tool for measuring and controlling ink flow performance.

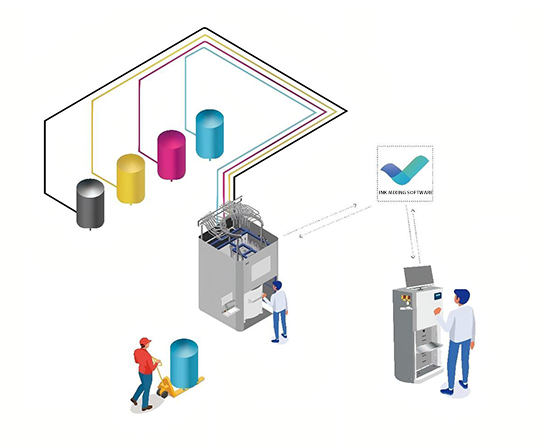

1.Automated Ink Dispenser (Up to 48 heads; Accuracy: 30kg/±1g, 300kg/±5g)

2.Industrial Mixer

3.Intermediary Tank

1.Establish a color difference database, verify new formulas, and create electronic files.

2.Enter the original ink return data into the system, manage the data digitally, and quickly and accurately search for potential ink returns.

3.Use a color display device and printing machine to control colors and optimize color difference data.

4.Conduct training on how to operate the automatic ink mixing system software.

5.Conduct training on how to operate the color matching software.

Ⅳ、Value of the ink mixing system:

Precision-driven ink dispensing systems deliver measurable ROI through operational excellence:

1.↑ 80% First-Pass Approval Rate

Reduce press setup time by up to 70% and substrate waste with right-first-time color matching.

2.Precision On-Demand Production

Eliminate batch variances through automated formulation execution, reducing residual ink generation by 30-50% while minimizing manual interventions.

3.Intelligent Residual Ink Management

Maintain <5% residual inventory via AI-powered retrieval algorithms and real-time utilization tracking.

4.ERP-Integrated Workflow Automation

Enable batch optimization, residual ink redeployment, and touchless order processing through bidirectional SAP/Oracle integration.

5.Granular Cost Intelligence

Automate ink consumption tracking with job-level cost attribution, enabling precise P&L visibility and waste auditing.