A manual colorant dispenser is a simple color mixing machine for paint that relies on manual operation to dispense and mix color paste. It is primarily used in the paint and ink industries. It precisely adds concentrated color pastes of different colors to the base paint according to the recipe to achieve the target color. Designed for color matching centers, manual color dispensers are high-precision, economical, and semi-automatic color dispensers, featuring high accuracy and excellent stability.

1. Core Features

Purely mechanical:

No motor, no circuit board, and no power or compressed air required.

The core component is a manual dispensing head made of metal or plastic (usually with a joystick or push-button handle).

Manual Operation:

Color mixing accuracy and speed rely entirely on the operator’s experience, skill, and attentiveness.

The operator manually adjusts the joystick or lever to control the dispensing of the color paste.

Depending on the color paste packaging:

Standard color paste cans/bottles are used (usually cylindrical cans with a pierceable seal).

The dispensing head must match the specifications of the color paste can.

2. Basic Working Principle

Installing Colorant Cans:

The operator manually installs cans of different color concentrates onto the corresponding dispensing heads of the color mixing machine.

Manual Dispensing Colorant:

The operator manually cranks a rocker or presses a handle according to the weight or volume required by the recipe.

This action drives a piston or gear mechanism inside the dispensing head, squeezing the colorant from the can and causing it to drip or flow into the paint mixing tank below (containing the base paint).

Repeated Dosing:

According to the recipe sequence, the operator sequentially operates the dispensing heads to add the required type and amount of colorant.

Uniform Mixing:

After all colorants have been added, the operator manually stirs (or uses a shaker) the paint mixing tank to thoroughly mix the colorants and base paint, ultimately achieving the desired color.

3. Core Components Typically Include:

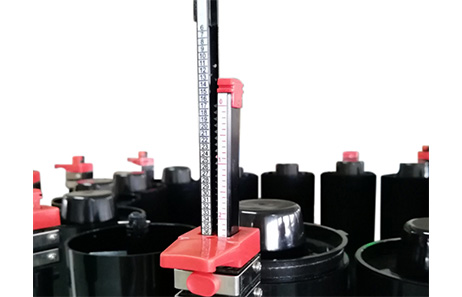

Colorant Rack/Base: Holds cans or bottles of various colorant concentrates (toners).

Manual Metering Pump: Installed on each colorant can. The operator manually dispenses the colorant by pressing or rotating the pump lever/handle, dispensing it drop by drop, milliliter by milliliter, or by the number of “shots” (pumps).

Mixing Container: Typically a mixing cup or bucket, it holds the base paint (white or clear) and the added colorant.

Stirring Tool: A manual stirring rod or paddle used to thoroughly mix the colorant and base paint.

Formula Booklet/Color Card: Provides a reference recipe for the target color (typically indicating the type of colorant to be added and the approximate amount or number of pumps).

Electronic Scale (Optional): For increased accuracy, some manual color mixing systems utilize an electronic scale to measure the colorant.

Although manual color mixers are not as efficient and accurate as fully automatic color mixers, they still offer some significant advantages for specific scenarios and needs:

1. Low Cost:

Low initial investment: This is their most core advantage. The purchase price of a manual color mixer is significantly lower than that of a fully automatic color mixer of the same level, making it a more viable option for small shops, startups, or one-person studios with limited budgets.

Low Maintenance Cost: Their simple structure, lacking complex motors, circuit boards, pumps, and other components, requires minimal maintenance and repair costs (typically requiring only simple, consumable parts like seals).

Low Consumable Cost: The amount of solvent required for cleaning is typically much less than that required for automatic color mixers.

2. Easy to Learn:

The operating principle is intuitive, and the operation steps are relatively simple (primarily manually turning a joystick or flipping a valve), allowing new employees to quickly learn and requiring minimal training.

No complex software or programming knowledge is required.

3. Compact and Portable:

Small in size and light in weight, they take up minimal space, making them ideal for shops with limited space. Portable, suitable for services requiring small-scale color mixing on-the-go (such as on-site touch-ups).

4. High Flexibility:

Small-batch color mixing is cost-effective: For small-area touch-ups requiring only a few milliliters or tens of milliliters of paint, manual machines can quickly and directly perform the task, eliminating the complex piping cleaning and startup procedures of automated machines, saving time and consumables.

Not restricted by a formula library: Operators can manually control the amount added based on experience or color charts, rather than relying entirely on a preset electronic formula library. This provides flexibility for unconventional colors or older colors without electronic formulas (although this requires operator experience).

High Compatibility: Colorants are generally not tied to a specific brand or type (as long as the colorant packaging fits the dispenser head), allowing users to choose colorants from different suppliers.

5. High Durability:

The simple mechanical structure and lack of sophisticated electronic components make them generally very rugged and durable, with a long service life and less prone to downtime due to electronic failures.

6. Easy to Clean and Maintain:

The open structure and limited components make cleaning and routine maintenance (such as replacing seals) relatively easy and user-friendly.

1. Small Car Repair and Detailing Shops:

Applications: Small scratch repairs, bumper repairs, and spot touch-ups,tinting paint.

Reason: Small paint volumes are required (often just tens to hundreds of milliliters), and color variations are numerous (colors vary significantly across brands, years, and models). Manual liquid dispenser machine offer the flexibility to mix small batches of specific colors, with a low initial investment, making them suitable for small shops or individual technicians with limited business volume. Experienced technicians can precisely match old or special car paints.

2. Furniture Manufacturing and Renovation Factories/Workshops:

Applications: Custom furniture production, restoration of old furniture, sample color testing, and small-batch orders for special colors.

Reason: Furniture color requirements are diverse and highly personalized, with frequent small-batch production. Manual mixer machine for paint allows for quick response to custom requests and fine-tuning of colors to achieve customer satisfaction. The cost is significantly lower than deploying automated production lines for each color or frequently purchasing pre-mixed paints.

3. Building Renovation and Painting Teams:

Scenario: On-site wall repairs, small area repainting, small-scale color matching of special effect paints (such as stone faux paint and artistic paint), and matching special color samples provided by the client.

Reason: Portability is key. Construction teams can bring manual color mixers to the job site to instantly mix, test, and fine-tune colors based on on-site lighting and wall conditions, ensuring the repaired area blends perfectly with the existing paint finish. Reliance on a fixed color mixing center is eliminated.

4. Building Materials Markets/Hardware Stores/Paint Retailers:

Scenario: Providing color mixing services for retail customers in small batches (e.g., less than 1 liter), especially when color requirements are less precise (such as interior paint or fence paint) or when on-site fine-tuning is required.

Reason: Lowering the service barrier. For retail locations with low customer traffic or infrequent color mixing needs, manual color mixers are an economical option for providing value-added services without the high investment and maintenance costs of automatic automatic paint mixing machine

5. Art Studio and Model Making:

Applications: Artist creation, mural painting, model painting (model aircraft, model ships, figurines), and painting crafts.

Reason: Requires extremely small amounts of special colors, non-standard colors, or metallic or pearlescent colors. Manual droppers allow precise control of a few drops of colorant to create unique artistic effects, offering far greater flexibility than the smallest measurement unit of an automatic machine.

6. DIY Enthusiasts and Home Users:

Applications: Minor home wall repairs, repurposing, and painting handicrafts.

Reason: The lowest-cost option. DIY users typically only need to mix once or a few times, and the amount used is very small. Manual color mixing kits are affordable, relatively intuitive to use (especially when simple recipes are provided), and meet basic personalized needs.

7. Teaching and Training:

Applications: Skills development for painters, colorists, and art students.

Reason: A fundamental tool for learning color theory. Manual operation forces trainees to carefully observe color changes, understand colorant properties, and master mixing ratios and fine-tuning techniques. This is an effective way to develop a keen eye and solid foundational skills, allowing them to transition to automatic color mixing machines.

8. Color Mixing with Special Bases or High-Viscosity Materials:

Scenario: Mixing epoxy floor paint, high-viscosity industrial coatings, special functional coatings, etc.

Reason: Certain high-viscosity or specially formulated bases may not be suitable for or may damage the precision pumps and piping of automatic color mixing machines. Manual pumps are more adaptable to these materials and offer greater controllability.

9. Remote Areas or Areas with Weak Infrastructure:

Scenario: Rural areas, outdoor construction sites, and locations with unstable power supply.

Reason: Completely independent of electricity. Color mixing can be performed with just the base paint and colorant, making it the only viable option in such environments.

10. As a Supplement to Automatic Color Mixers:

Scenario: In stores or factories equipped with automatic color mixing machines. Reasons:

Fine-tuning: When the color produced by the automated machine deviates slightly from the standard color palette, experienced technicians manually add a few drops of colorant for precise fine-tuning.

Minimum Batches/Test Colors: Mixing extremely small quantities (e.g., a few milliliters) for test color comparisons, avoiding the automated machine’s minimum metering limitations and residual waste in the pipeline.

Special Colors/Off-Formula Colors: Mixing extremely complex or customized colors not included in the automated machine’s recipe library.

Emergency Backup: Maintaining basic color mixing services as a backup in the event of automated machine failure or maintenance.