Does this sound familiar? You design a stunning package with vibrant metallic effects. Or you create eye-catching graphics using neon-bright fluorescent inks. But when these special inks run through your automated dispensing system, the result is disappointing.

The metallic finish looks dull and flat. The fluorescent color lacks its usual punch. To make matters worse, you face constant clogs, pump wear, and downtime.

The problem isn’t the ink. The problem is that a standard automatic dispensing system is engineered for conventional pigments. Metallic and fluorescent inks have unique personalities. They require a different approach to automated fluid handling.

This guide explains the core challenges and provides a specialized methodology. You will learn how to configure a precision dispensing system that protects these valuable inks. The goal is to ensure every batch matches the brilliant quality of your design.

To find the right solution, you must first understand the source of the problems. These are not your standard CMYK inks.

The shimmer of a metallic ink comes from tiny, flat aluminum or bronze flakes suspended in the vehicle. This physics creates two major headaches for automated dispensing equipment:

1.Rapid Settling and Clogging: These dense flakes sink quickly. In a static dispensing system reservoir, they form a hard cake at the bottom. This leads to inconsistent color and, worse, blocked lines and valves. Your automated filling system cannot maintain accuracy if the material is not homogeneous.

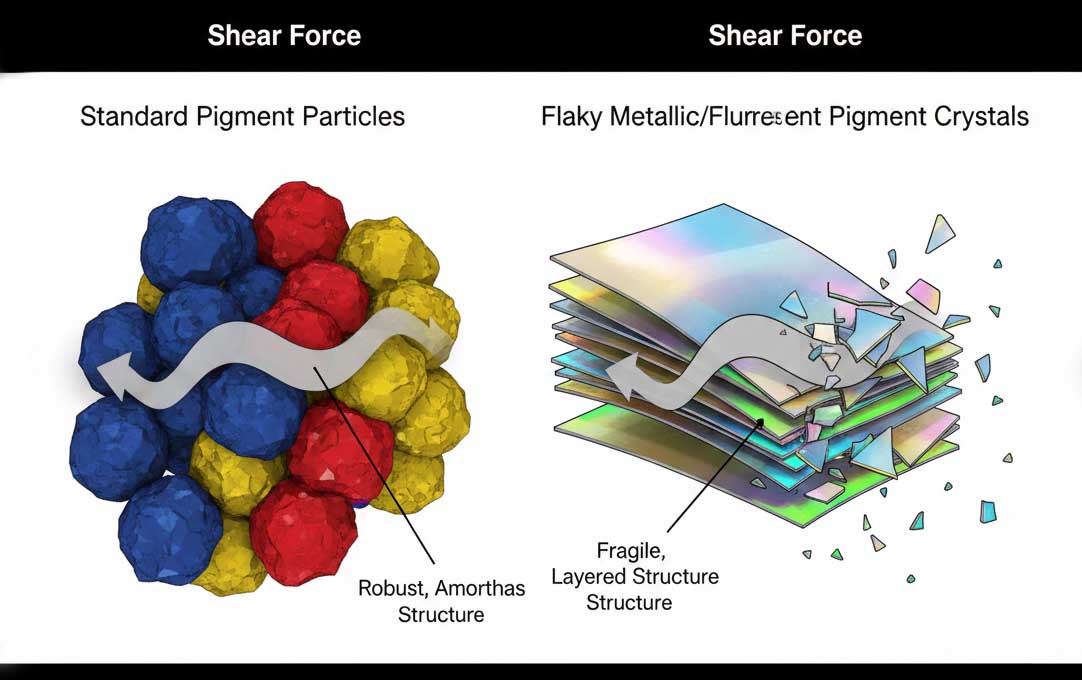

2.Shear-Induced Damage: High-shear pumps and aggressive mixers can bend, curl, or shred the delicate flakes. Once their physical structure is damaged, they lose their ability to reflect light. The ink goes from a brilliant metallic to a dull grey. No automatic color dispensing software can fix this physical degradation.

Fluorescent inks glow because their pigments absorb UV light and re-emit it as visible light. This special chemistry is fragile.

1.Mechanical Shear Kills Luminosity: The crystal structure of fluorescent pigments is sensitive to mechanical shear force. The intense grinding action inside some types of dispensing pumps can destroy this structure. The ink may still look colored, but its radiant “pop” and brightness fade significantly.

2.Heat Leads to Permanent Fade: Friction from pumps and recirculation in a closed-loop dispensing system generates heat. Excessive heat accelerates the aging process of fluorescent pigments, causing a permanent loss of vibrancy. This directly contradicts the goal of a stable automated production line.

Both ink types are often thicker (higher viscosity) and can be sensitive to solvents. This complicates their reliable use in any automated dispensing and mixing system.

You cannot just slow down a standard system. Handling these inks requires a purpose-built approach across hardware, process, and control.

The right components form the foundation of a protective automated dispensing solution.

The Heart of the System: Low-Shear Pump Technology

Forget gear pumps or centrifugal pumps. For automated dispensing of viscous materials like these, a peristaltic (tube) pump is ideal. It works by rollers compressing a flexible tube, gently pushing the fluid forward. The ink only contacts the smooth tube interior, minimizing shear. It also creates a seal-less, contamination-free environment, perfect for precision chemical dispensing.

Preventing Settlement: Continuous Anti-Settling Loops

Install a slow, continuous recirculation loop between the main bulk dispensing tank and the dispensing head. A gentle pump keeps the ink moving just enough to prevent flakes or pigments from settling. This ensures the material fed to the point-of-use dispenser is perfectly uniform for every batch.

Contact Materials: Smooth and Inert

Specify highly polished 316L stainless steel or PTFE (Teflon) for all wetted parts—tanks, pipes, valves, and fittings. Ultra-smooth surfaces prevent particles from sticking and building up. Inert materials avoid chemical reactions that could alter the ink. This is critical for reliable automated dispensing.

With the right hardware, you must define the correct “operating instructions.”

Optimizing Flow Rate and Pressure

Through testing, find the minimum effective flow rate and system pressure for each ink. The rule is: use the lowest possible settings that still prevent settling and ensure consistent metered dispensing. This minimizes stress on the sensitive pigments.

Gentle Mixing and Agitation

If in-line mixing is needed, use only low-speed agitators or static mixers. Never use a high-shear homogenizer. The goal is uniformity, not particle size reduction. This philosophy is key for automated dispensing of shear-sensitive fluids.

Rigorous Temperature Control

Integrate temperature sensors at key points (reservoir, pump outlet). Set alarms to alert operators if the ink temperature approaches a critical threshold. Controlling heat is a non-negotiable part of automated process dispensing for fluorescent inks.

Lock in your perfect process and make it repeatable, batch after batch.

Creating Digital “Ink Passports”

Within the automated dispensing system’s control software, create a dedicated profile for each special effect ink. This profile stores its unique set of validated parameters: ideal flow rate, recirculation settings, and cleaning procedure. Operators simply select the profile, ensuring perfect automated batch dispensing every time.

Implementing Preventive Cleaning Cycles

Program more frequent and thorough automated purge and cleaning cycles than for standard inks. Use compatible, dedicated cleaning fluids to fully remove any residual flakes or pigments from the lines. This prevents cross-contamination and clogging, maximizing uptime for your automated production dispensing system.

Ensuring Full Traceability

A modern automated dispensing system should log all process data. This includes batch numbers, actual dispensing weights versus targets, and system parameters. If a finished print has a gloss or color issue, you can trace it back through the dispensing system data log. This enables root-cause analysis and proves process consistency.

Investing in a tailored automatic dispensing system for these inks is not just an expense. It’s a strategic move that delivers measurable returns.

Consistent, Premium Quality: Guarantee that every print job has the brilliant metallic sheen or radiant fluorescence you designed. This builds brand reputation and justifies higher price points.

Reduced Waste and Downtime: Dramatically cut losses from spoiled ink, clog-related stoppages, and rejected batches. Gentle handling also extends the shelf-life of expensive specialty inks.

Unlocked Creative Potential: Give your design team the confidence to specify stunning special effects, knowing production can deliver them reliably every time. This wins new business.

Successfully handling metallic and fluorescent inks requires a mindset shift. You are not just moving fluid from a tank to a press. You are carefully conveying a delicate, performance-critical material.

Your automated dispensing system must transition from a “bulk transporter” to a “specialized caretaker.” The priority moves from maximum speed to maximum preservation of the ink’s inherent properties.

In a competitive print market, the ability to master these challenging effects is a powerful differentiator. It allows you to command premium work and build a reputation for unparalleled quality. Partnering with the right automated dispensing technology is the key to making this possible.

Taming metallic and fluorescent inks requires expertise and the right technology. Our specialists have deep experience in configuring precision automated dispensing systems for the most challenging fluids in the printing industry.

[Click Here to Download Your Free Whitepaper]

Get a Personalized Consultation: Have a specific challenge with your current ink dispensing setup? Schedule a free, no-obligation consultation with our application engineers. We’ll analyze your needs and provide actionable insights.

[Book Your Free Consultation with a Dispensing Expert Today]