Have you ever looked at a finished product—perhaps a high-end tobacco package or a sleek piece of furniture—and felt a wave of frustration?

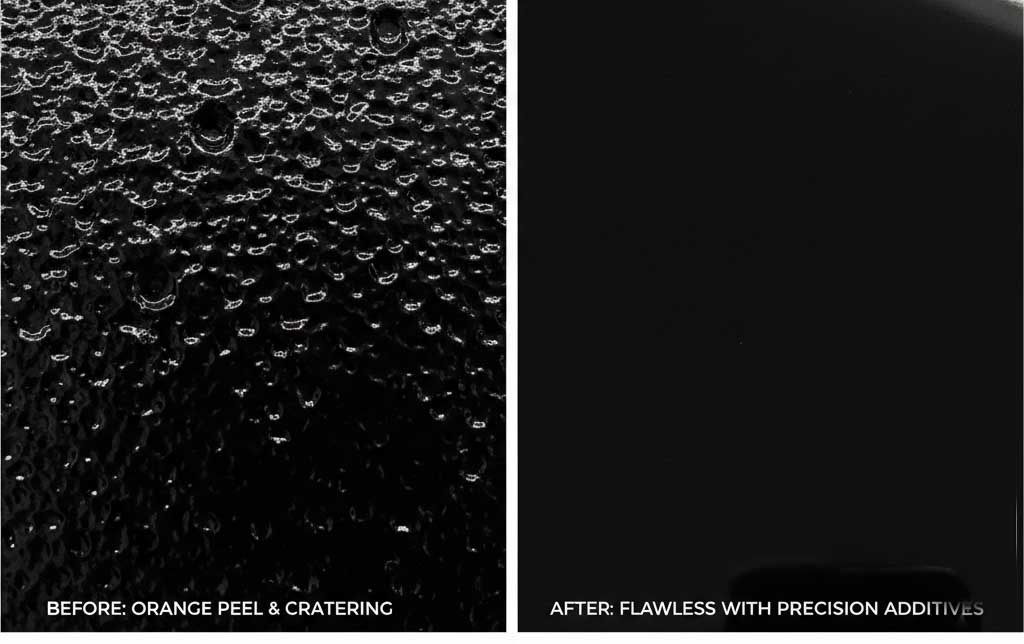

The surface is supposed to be mirror-smooth. Instead, it’s covered in a bumpy, rough texture known as orange peel. Or worse, you see tiny “craters” (pinholes) that look like a needle poked the wet film.

Why does this happen?

You’ve checked the temperature. You’ve adjusted the spray pressure. You’ve even swapped the main varnish. But the problem persists.

The culprit isn’t usually your main material. It’s the “hidden 1%”. We are talking about additives:

Leveling agents

Defoamers

Matting agents (Silica)

Driers

Anti-scratch additives

Even though these make up a tiny fraction of your formula, they control the surface tension and rheology. If they aren’t handled with precision, your coating quality will never be consistent.

In the old days, a “master technician” would add additives by feel. They’d use a beaker or just “eyeball” it. In a modern high-precision production line, this is a recipe for disaster.

Most people measure liquid additives by volume (liters or milliliters). This is a mistake.

Liquids expand and contract with temperature. A thick silicone leveling agent behaves differently at 15°C than at 30°C. If you use a measuring cup, you are guessing, not measuring.

High-performance additives are often thick or “syrupy.” When you pour them out of a container, a significant amount stays stuck to the walls. If your recipe calls for 10g and 2g stays in the beaker, you’ve just missed your target by 20%.

Ever see white specs in a matte finish? That’s Matting Agent (Silica) clumping.

Standard stirrers don’t have the “bite” to break down these micro-clumps. Without high-shear mixing, these clumps become “seeds” for cratering and surface defects.

To stop “orange peel” and “craters” forever, you need to move from “art” to “science.” Here is the professional workflow for additive dosing and dispersion.

If you want consistency, you must stop measuring by volume and start measuring by weight.

Why Weight? Mass is constant. 100 grams is 100 grams, regardless of whether the liquid is cold, hot, thick, or thin.

The Solution: Implementing an Auto Dispenser Machine with Gravimetric Technology

Modern systems use high-precision load cells. They monitor the weight in real-time. If the recipe calls for 0.5g of a wetting agent, the system delivers exactly 0.5g.

Anti-Drip Technology

To avoid “trailing” or “stringing” of thick additives, look for valves with snuff-back (suck-back) functions. This ensures every drop goes into the mix, not on the rim of the tank.

Adding the ingredient is only half the battle. You have to “activate” it.

Mixing vs. Dispersing

Mixing moves the liquid around. Dispersing breaks particles down. To prevent orange peel, your additives must be perfectly integrated into the varnish at a molecular level.

High-Shear Blades

You need a Cowles dissolver or a high-speed dispersion disc. These blades spin fast enough to create a “donut” vortex. The tips of the blades tear apart pigment aggregates and additive clumps.

Inline High-Shear Mixers

For large-scale production, an inline rotor-stator mixer is a game-changer. It forces the varnish and additives through a tiny gap at high velocity. This ensures uniform surface tension across the entire batch.

The final step is removing human error from the equation.

Digital Formulation

Store your recipes in a central “brain” (PLC or Batch Management System). The operator doesn’t type in numbers; they just scan a barcode.

Traceability and “Birth Certificates”

If a customer complains about cratering three months from now, can you prove how much defoamer was in that specific batch?

A digital system logs every gram added. This is your “Data Black Box.” It turns production into a digital asset.

If you are researching solutions, these are the technical terms that matter:

Coating surface tension modifiers

Automated liquid additive dispensing

Matting agent dispersion techniques

UV varnish orange peel solutions

Gravimetric dosing for coatings

High-shear mixing for paints and inks

Is a precision dosing system an “extra cost”? No. It’s a profit generator.

| Benefit | How it Saves Money |

| Reduce Waste | Save up to 20% on expensive additives like UV initiators or flow agents. |

| Lower Rejection Rate | Stop throwing away “orange peel” batches. |

| Faster Changeovers | Switch from high-gloss to matte in minutes, not hours. |

| Consistent Quality | Build a reputation for perfection that wins high-end clients. |

By upgrading to a high-speed auto dispenser machine, your facility can reduce chemical waste by up to 20% while ensuring a flawless surface finish every time.

In the competitive world of printing and industrial coating, “good enough” is no longer enough. The orange peel effect and surface craters are signs of a process that is out of control.

By focusing on the “last 1%”—the additives—you transform your production line. You move from guessing to knowing. You move from fixing problems to preventing them.

Are you struggling with inconsistent gloss levels or surface defects that won’t go away? Don’t let a 1% additive ruin 100% of your product.

Our expert engineers specialize in additive dosing and dispersion technology. We can help you identify the “bottleneck” in your current setup and suggest a roadmap to precision.

👉 [Contact Our Experts for a Free Consultation]

Let’s lock your uncertainty into a “data black box” and get your coatings back to a perfect finish.

Common FAQs about Coating Additives:

How do I stop orange peel in UV coatings?

Focus on the leveling agent concentration and ensure your dispersion speed is high enough to lower the viscosity during application.

What is the best way to add matting powder?

Always pre-disperse matting agents into a “mother liquor” using a high-shear mixer before adding them to the final batch.

Can I automate the addition of micro-quantities?

Yes. Modern micro-dosing valves can accurately dispense as little as 0.05g of material with 99% repeatability.