If you work in the world of paints, inks, or coatings, you know the ghost. It’s a phantom that haunts production floors, gives quality managers sleepless nights, and strains relationships with your most important clients. This ghost has a name: Batch Color Variation.

You mix a perfect batch. The color matches the standard exactly. The client is happy. Then, you run another batch. The formula is identical. The raw materials are from the same supplier. But the color is off. Just a little. Maybe it’s a shade darker. Maybe the hue is slightly different. It’s a subtle shift, but it’s enough to cause rejection, rework, and reputational damage.

You’ve checked the pigments. You’ve calibrated the mixers. You’ve empowered your quality control team. Yet, the problem persists. Why?

The answer often lies not in the what of your formulation, but in the how of its application. The culprit, in most cases, is an unseen, constantly fluctuating process variable: Viscosity.

In this deep dive, we will explore why viscosity is the master key to color consistency. We will dismantle the shortcomings of traditional control methods. And most importantly, we will reveal how a technological solution—the NP5.0-MIN-SE Intelligent Viscosity Controller—acts as a relentless guardian of your formula, finally banishing the ghost of batch variation for good.

To solve a problem, you must first understand its root cause. Viscosity is simply a measure of a fluid’s resistance to flow. Think of water (low viscosity) versus honey (high viscosity). But in industrial applications, viscosity is anything but simple. It is a dynamic, living characteristic of your paint or ink that directly dictates final color performance in several critical ways.

1. Pigment Suspension and Distribution: The Fight Against Gravity

Pigments are solid particles. In a perfect world, they would stay evenly distributed throughout your liquid base. We do not live in a perfect world. Gravity constantly pulls these particles downward.

When Viscosity is Too Low: Your fluid lacks the “body” or “thickness” to hold pigments in suspension. They settle at the bottom of tanks, drums, and hoses at an accelerated rate. Imagine a tank of paint. The first drum you pull from the top might be pigment-deficient, resulting in a lighter, weaker color. The last drum from the bottom will be a concentrated sludge of pigment, creating a much darker, stronger color. This is a primary source of batch-to-batch and even within-batch inconsistency. The fluid at the start of the run is fundamentally different from the fluid at the end.

2. Film Thickness and Opacity: The Final Coat is Everything

The ultimate test of your product happens on the substrate—be it paper, plastic, metal, or wood. The color we see is a function of light interacting with the pigment in the dried film.

The Direct Relationship: Viscosity directly controls the applied wet film thickness. Higher viscosity fluids resist spreading, leading to a thicker coating. Lower viscosity fluids flow and spread easily, creating a thinner coating.

The Color Impact: A thicker film lays down more pigment per unit area. This makes the color appear more saturated, darker, and opaque. A thinner film allows more of the substrate to show through, making the color appear lighter, less saturated, and potentially patchy. Even if your formula has the perfect pigment ratio, an inconsistent film thickness, driven by viscosity swings, will create a visibly different color. It’s like putting on one coat of paint versus two coats; the result is never the same.

3. The Evaporation Problem: A Shifting Foundation

This is perhaps the most dynamic challenge, especially in printing and high-speed coating applications. Solvents or diluents in your ink or paint evaporate during the process.

As the solvent leaves, the percentage of solids in the mixture increases. This causes the viscosity to rise continuously. A batch that starts at the perfect viscosity can become too thick within minutes. This leads to application problems like poor leveling, orange peel, and, crucially, a darker color due to the higher pigment concentration and thicker film.

The Traditional “Solution” and Its Flaws

For decades, the industry’s answer to this has been manual intervention. An operator periodically takes a sample—perhaps every hour—and uses a cup viscometer to check the flow time. If the viscosity is high, they add a predetermined amount of solvent. This method, while well-intentioned, is fundamentally flawed:

It’s Reactive, Not Proactive: You are always fighting a problem that has already existed for some time. The process has been running out of spec for minutes before you even detect the issue.

It’s Inconsistent: Human timing and technique vary. One operator might add a little more solvent than another.

It Promotes Over-Correction: To avoid constant adjustments, operators often add too much solvent at once. This causes a violent “sawtooth” pattern in viscosity: a sharp drop (over-dilution) followed by a slow, steady climb as solvent evaporates, then another sharp drop. This cycle of “too thin -> too thick -> too thin” is a recipe for color chaos.

It’s clear that to achieve perfect color consistency, we need to move beyond this archaic, hands-on approach. We need a system that provides constant, silent, and precise vigilance. We need an automated guardian.

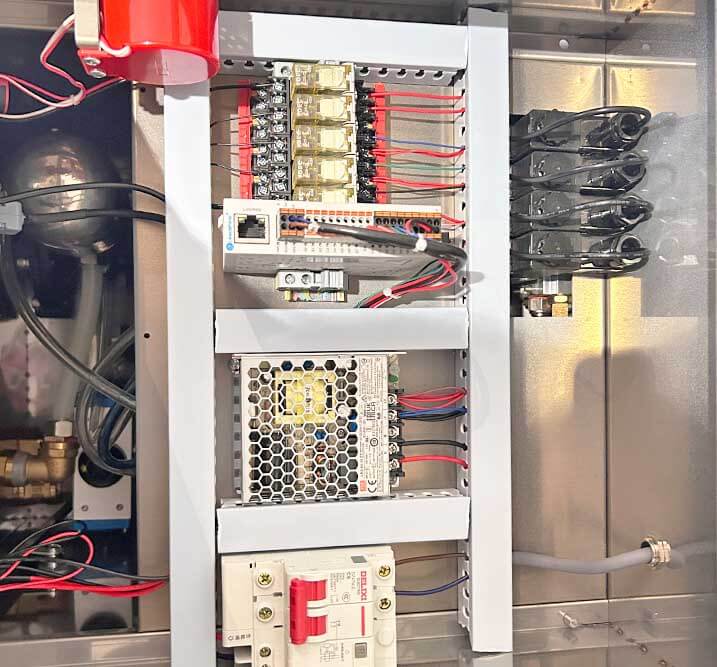

The NP5.0-MIN-SE is not just a sensor; it is a complete, closed-loop automation system. It replaces human guesswork with robotic precision. Its operation can be broken down into a simple, relentless three-step cycle: Sense, Decide, Act.

Step 1: SENSE – The Unblinking Eye

The core of the NP5.0-MIN-SE’s innovation is its built-in viscometer. This is not a separate, offline device. It is directly plumbed into the main fluid line, sitting between the circulation tank and the printing, coating, or laminating equipment.

This strategic placement is crucial. It measures the viscosity of the fluid as it is about to be applied. This is the most critical measurement point.

And it doesn’t measure just occasionally. It performs a fresh, precise measurement every 20 seconds. This constant, real-time data stream provides a crystal-clear picture of what is happening in your process. There are no more blind spots. There is no more guessing.

Step 2: DECIDE – The Instantaneous Brain

The viscosity data flows instantly into the controller’s integrated processor—the brain of the operation. This brain compares the live viscosity reading against your pre-set ideal target value.

The logic is simple, but the execution is brilliant. The moment the measured value drifts above the setpoint for a mere 0.1 seconds, the system makes a decision: “It’s time to act.” This lightning-fast judgment ensures that any deviation is caught at its very inception.

Step 3: ACT – The Precise Hand

Upon command, the controller’s solenoid valve or pump activates, drawing a small, metered amount of pure solvent from its source and injecting it directly into the circulation tank.

This is where the NP5.0-MIN-SE truly outshines manual methods. It doesn’t dump in a large quantity of solvent. It adds a tiny, precise amount. This micro-adjustment is enough to gently nudge the viscosity back toward the setpoint without overshooting.

The Perfect Cycle:

This “Sense -> Decide -> Act” cycle repeats every 20 seconds, 24/7. The system doesn’t get tired. It doesn’t take breaks. It maintains your viscosity not as a jagged “sawtooth” wave, but as a smooth, flat, perfect line on a graph. This is the visual representation of consistency. This is the foundation of batchless color.

(Imagine a diagram here showing the fluid loop: Circulation Tank -> Pump -> NP5.0-MIN-SE (with “Sense” icon) -> Printing/Coating Head -> Return to Tank. A “Solvent Supply” line connects to the NP5.0-MIN-SE with an “Act” icon, and a “Data” line goes from the controller to a “Brain” icon.)

Let’s make the comparison crystal clear. The transition to an intelligent viscosity controller is not a minor upgrade; it’s a revolution in process control.

| Feature | The Traditional Manual Method | NP5.0-MIN-SE Intelligent Control |

|---|---|---|

| Measurement | Periodic, offline, manual sampling. Prone to human error and delay. | Continuous, inline, automatic measurement every 20 seconds. No delay, no error. |

| Control Action | Reactive, bulk solvent addition. Causes a “sawtooth” pattern of over- and under-correction. | Proactive, micro-solvent additions. Maintains a smooth, flat-line viscosity. |

| Risk of Over-dilution | Very High. Operators often add too much to avoid frequent checks. | Eliminated. The system’s precision prevents over-thinning, protecting product quality. |

| Labor Dependency | Fully dependent on skilled operators. Vulnerable to shift changes and fatigue. | Fully automated. Frees up skilled staff for more valuable tasks. Runs consistently across all shifts. |

| Data & Insight | Minimal. Usually just a handwritten log with a few data points per shift. | Rich data stream with optional data acquisition. Enables process optimization and OEE tracking. |

While eradicating batch color variation is a massive win, the benefits of implementing the NP5.0-MIN-SE cascade throughout your entire operation, delivering a rapid and compelling return on investment.

1. Massive Reduction in Waste and Rework

Rejected batches, off-spec product, and customer returns are a direct drain on your profitability. By guaranteeing consistency from the first drum to the last, the controller slashes these costs to zero. The value of a single saved batch can often justify the investment.

2. Dramatic Solvent Savings

This is a direct and calculable cost saving. Manual addition is wasteful. The NP5.0-MIN-SE’s micro-additions ensure that you use the absolute minimum amount of solvent required to maintain viscosity. The Automatic Solvent Consumption Statistics feature provides you with the exact data to prove these savings to your finance department.

3. Unlocking Higher Production Efficiency

The controller enables a true “lights-out” operation for this part of your process. There are no more停机 for viscosity checks. No more slowdowns while operators fiddle with additions. The line runs faster and smoother, increasing your overall equipment effectiveness (OEE) and allowing you to produce more with the same assets.

4. Empowering Your Digital Transformation

The optional Data Acquisition and Transmission feature is a gateway to Industry 4.0. Viscosity is no longer just a control parameter; it becomes a valuable data point. You can track it over time, correlate it with other process variables, and use it for predictive maintenance. For example, a gradual drift in viscosity control might indicate a pump is wearing or a filter is clogging, allowing you to fix it before it causes downtime.

5. The Ultimate Flexibility: The Multi-Function Two-in-One Proportional Machine

The document also mentions a powerful companion system. This machine tackles solvent management at an even higher level.

Solvent Mixing and Proportional Function: It can automatically blend up to five different solvents using precise weight-based metering. This ensures your dilution solvent itself is perfectly consistent, removing another potential variable.

Recycled Solvent Reproportioning Function: Recycled solvents are a great way to save money, but their inconsistent ratios make them unsuitable for direct use. This machine performs a secondary, intelligent proportionality on recycled solvents, bringing them back to a usable standard. This closes the loop on sustainability and cost-saving, working in perfect harmony with the viscosity controller.

The NP5.0-MIN-SE is a specialist, and it excels in demanding environments where color and consistency are non-negotiable.

Packaging Printing: Imagine a global brand like Coca-Cola. Their specific red is a priceless asset. The NP5.0-MIN-SE ensures that every can, every bottle, and every piece of packaging, produced in any factory around the world, on any day, bears the exact same red. It protects brand equity at the production level.

Publication Printing: In high-speed magazine and catalog production, it maintains the density of black and cyan inks, ensuring text is sharp and images are consistent across millions of copies.

Industrial Wood and Metal Coatings: It guarantees that the final color and sheen of a coated product are uniform across the entire production run, eliminating the “patchy” look that plagues manufacturers of furniture, automotive parts, and appliances.

Flexible Packaging and Laminating Adhesives: While not colored itself, an adhesive’s viscosity is critical for application weight. The NP5.0-MIN-SE ensures a consistent coat weight, preventing bond failures or wasteful over-application, which is crucial for the integrity of food and pharmaceutical packaging.

For too long, the industry has accepted batch color variation as an unavoidable cost of doing business. We have blamed raw materials, blamed the environment, and blamed human error. But the true enemy has always been a lack of control over a fundamental process variable.

The NP5.0-MIN-SE Intelligent Viscosity Controller changes the game. It is not an incremental improvement. It is a definitive solution. It acts as the unwavering, precise, and automated guardian of your formulation.

It ensures that the color you design in the lab is the color that goes out the door, every single time. It transforms viscosity from a source of anxiety into a pillar of reliability.

Stop chasing the ghost of batch variation. Stop wasting money on rework and excess solvent. It is time to move from reactive guesswork to proactive, intelligent control.

The technology is here. The guardian is ready. It’s time to tame the unseen variable and declare your independence from inconsistency once and for all.