Core objectives: Gentle mixing, homogenization, prevention of settling, heat transfer without breaking particles or dispersing agglomerates.

Working principle: By generating macroscopic fluid movement, the materials in the whole container undergo gentle convection circulation, so as to achieve uniform distribution of ingredients. There is very little shear force applied to the material during the process.

Typical equipment:

Paddle Mixer: Simple construction, suitable for simple mixing and preventing settling.

Turbine Mixer: More efficient than paddle mixer and can produce stronger fluid movement, but it still belongs to the low shear category and is suitable for mixing medium and low viscosity liquids.

Portable Mixer: Highly flexible, it is often used for paint mixing, ingredients and anti-settling of large storage tanks.

Static Mixer (Static Mixer): It has no moving parts and relies on fluid flowing through internal fixed elements to achieve division and merging to achieve mixing purposes. It is often used for online mixing in continuous production lines.

Applicable scenarios:

Dilute the dispersed paint (add solvents or additives).

tinting of the finished paint.

Mixture of low viscosity varnish, solvent, water.

Anti-settling maintenance of products in large storage tanks.

Purchase Note:

It must never be used to disperse powdered pigments into liquids, otherwise particles and agglomerations that cannot be eliminated will be produced.

When selecting a model, focus on the Flow it generates rather than the shear force.

Core objectives: dispersion, deagglomeration, crushing, emulsification. Extremely high mechanical shear forces are used to quickly break powder agglomerates, allowing them to be uniformly dispersed into the liquid medium and achieve the desired fineness.

Working principle: Through the violent mechanical action between the high-speed rotating rotor and the closely fitted stator, or the impact and shear force generated by the high-speed rotating dispersion disk, the material is torn, crushed and dispersed.

Typical equipment:

High-Speed Disperser (HSD): The absolute main force in the field of industrial coatings. Its serrated dispersion disk forms a vortex under high-speed rotation, which coils the powder and applies shear force to achieve efficient dispersion. Suitable for medium to high viscosity slurries.

Rotor-Stator Mixer: Higher shear strength than HSD. The material is sucked into the narrow gap between the rotor and stator, and undergoes extremely strong shear, impact and cavitation, which can achieve ultra-fine dispersion and emulsification. Available as batch or in-line (pipeline).

Applicable scenarios:

Pigment dispersion: Dispersing titanium dioxide, various color pastes, fillers and other powders into the resin liquid is the core process of coating production.

Preparation of master slurry: Produce high-concentration pigment slurry.

Emulsion preparation: An immiscible liquid is prepared into a stable emulsion.

Purchase Note:

A lot of heat will be generated, so it is necessary to pay attention to the cooling capacity of the equipment (e.g. cooling jacket).

Air will be involved, and follow-up processes will be required for products that require defoaming.

The power and speed requirements are high, and the energy consumption is large.

For highly abrasive pigments (such as zinc-rich primers), wear-resistant materials (such as tungsten carbide coatings) need to be selected.

Core objective: To deal with extremely high viscosity materials, realize kneading, kneading and extrusion, and ensure no dead zone mixing.

Working principle: It does not rely on the generation of vortex currents (high viscosity materials cannot form vortex currents), but continuously brings the materials to the range of action of the stirring tool by mechanical means. Often with powerful torque and a “scraping wall” feature.

Typical equipment:

Double Planetary Mixer: The king of high viscosity mixing. The two stirring paddles not only revolve around the container, but also rotate themselves, forming a complex movement trajectory. The paddles usually fit closely to the kettle wall, which can continuously scrape up the material and achieve 100% mixing without dead zones. Ideal for materials ranging from paste to extremely high viscosity.

Kneader (Sigma Blade Kneader): Usually there is a “Z”-shaped or Sigma-shaped slot, and the two blades rotate in opposite directions and at different speeds, which strongly shears, squeezes and folds the material, and the mixing effect is very strong.

Applicable scenarios:

Ultra-high viscosity coatings (e.g. putty, sealant, epoxy glue, asphalt coating).

Paste and paste products.

High-end coatings that require vacuum defoaming.

Purchase Note:

Torque (torque) is the core parameter. The higher the viscosity, the greater the torque required and the greater the motor power.

Attention must be paid to the material of the kettle wall and the design of the scraper to ensure its self-cleaning and anti-adhesion ability.

The speed is usually slower and the main purpose is to mix thoroughly rather than disperse quickly.

This is the most basic and important area of customization, directly related to equipment durability, compatibility and product purity.

Material of part contacting material:

Standard option: 304 stainless steel. Suitable for most water-based coatings and non-corrosive occasions.

Advanced customization:

316 Stainless Steel: Significantly improves corrosion resistance to chlorides, solvents and acids and bases, making it the first choice for high-quality solvent-based coatings and specialty chemicals.

Duplex Steel/Hastelloy: Used in extremely corrosive conditions, costly.

Carbon steel lined with stainless steel/polymer material: For large tanks, in order to reduce costs, carbon steel fuselage can be lined with stainless steel or plastic.

Surface treatment: Polishing treatment (e.g. mechanical polishing, electropolishing) to higher surface finish (e.g. Ra < 0.4 µ m), reducing material adhesion and facilitating cleaning.

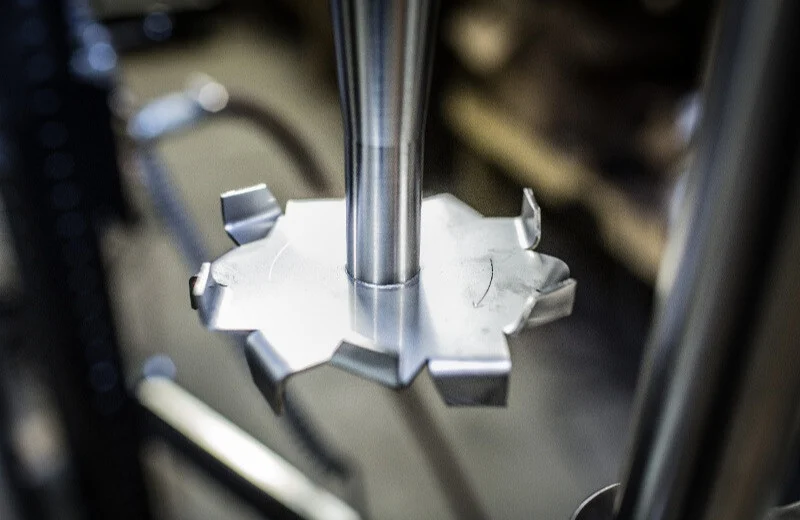

Material and design of stirring paddle/dispersion disk:

Material: In addition to the above stainless steel, for extremely abrasive materials, the paddles and dispersion disks can be coated with Tungsten Carbide (Tungsten Carbide) or sprayed with other wear-resistant alloys, and the life can be extended several times.

Design: Customize serrated shapes, angles, different numbers of dispersion discs, or different shapes of paddles depending on viscosity and process goals.

Sealing System:

Standard type: packing seal.

Customized:

Mechanical seal: It is almost a standard customization item for industrial coatings. More reliable, long life, prevent leakage.

Double End Face Mechanical Seal: The highest level of sealing option, which can inject a buffer between the two sealing surfaces to thoroughly prevent hazardous solvent leakage or air ingress, is a core requirement for explosion protection and safe production.

Sealing material: The material of the sealing ring is customized according to the chemical properties of the material to be solvent and temperature resistant.

Motor:

Explosion-proof rating: When handling solvent-based coatings, you must customize the explosion-proof motor and explosion-proof control cabinet. The grade shall be determined according to the division of site areas.

Power and torque: Customize the motor power and the output torque of the reduction gearbox according to the highest viscosity of the material rather than the average viscosity to ensure smooth start and operation under high viscosity conditions and avoid burning the motor.

Frequency Conversion Control: Customized frequency converter (VFD) to achieve stepless speed regulation, soft start/soft stop, and display rotational speed and torque for easy process optimization and repetition.

Lifting System:

Hydraulic Lift: Traditionally stable and powerful, suitable for heavy-duty mixing heads.

Electric lifting: cleaner, no risk of oil leakage, more precise control, is the trend of modern design.

HANUAL LIFT: For small, lightweight laboratory equipment only.

Stroke and height: Customize the lifting stroke according to the depth of the tank or reactor.

Installation method:

Floor-standing: The mainstream method of large dispersers, with excellent stability.

Platform Style: Mount the mixer on a platform that straddles the tank body to save space.

HANGER/CEILING MOUNT: For oversized tanks or where space is constrained.

Vacuum system:

The stirred tank is equipped with a vacuum cover and a vacuum pump, and vacuum defoaming is performed while stirring. This is essential for high-end finishes such as automotive paints and electronic paints that require absolutely no pinholes.

Heating and cooling system (jacket):

A jacket is designed on the wall of the stirring tank or inside the dispersion tray, which can be introduced into heat transfer oil or cooling water to accurately control the temperature of the material during the production process and prevent overheated gel or the need for heating to reduce viscosity.

Multiple agitator combination (two speed/two machine):

“Two-speed” concept: One motor drives two different shaped agitators (e.g. an anchor scraper + a dispersion disk) through a gearbox. At low speed, use anchor wall scraper to mix evenly, and at high speed, use dispersion disk to shear.

“Double machine” concept: Two independent mixers (such as a planetary mixer + a high-speed disperser) are installed on a kettle cover, which are independently controlled to realize the most complex mixing and dispersion process.

Control Panel:

Basic type: push button switch, tachometer.

PLC + touch screen (HMI) control: It can be customized and programmed to store the process formulas of a variety of products (rotation speed, time, temperature, rising and falling sequence, etc.), realize one-click production, reduce human error and ensure product consistency.

Data recording: Record key parameters in the production process to meet quality traceability and audit requirements.

6. Container (tank/kettle) customization

Material: Consistent with the body material options.

Shape and size: Customize the volume according to the batch, and choose dish bottom, flat bottom, tapered bottom, etc.

Mode of movement: Install casters (cart type) and make it into lifting bucket truck type, which is convenient to move between different stations.

Clear requirements: Define in detail your material attributes (viscosity range, composition, corrosiveness, abrasiveness), production process (dispersion, mixing, defoaming), capacity (batch size), safety requirements (explosion-proof) and budget.

Communicate with technical sales engineers: Discuss your needs with engineers from equipment suppliers in depth, and they can provide professional customized solutions.

Requirements for test machine: Provide material samples as much as possible and conduct test machine verification before customization at the supplier’s test center. This is the most critical step to ensure the feasibility of the customized solution.

Confirmation scheme: Review the technical scheme, drawings and configuration list provided by the supplier, and confirm all customization details.

With the above customization options, you can transform a standard industrial mixer into a dedicated equipment fully adapted to your production line, thus maximizing production efficiency and product quality.