Henan,China,25 Dec,2024-Henan Sightec Co., Ltd., a pioneer in intelligent coating solutions, has officially launched its groundbreaking fully automated unmanned specialty coating production line, setting new standards for precision and efficiency in the paint manufacturing industry.

Key Features of the Automated Production Process:

1.AI-Optimized Production Scheduling

Smart order sequencing algorithm prioritizes urgent custom color orders (RAL/Pantone) with 99.7% accuracy.

2.Closed-Loop Quality Control System

Integrated spectral analysis sensors automatically:

Detect color deviation (ΔE<0.5)

Adjust formula ratios in real-time

Replenish base components to meet exact weight specifications

3.Zero-Contact Material Handling

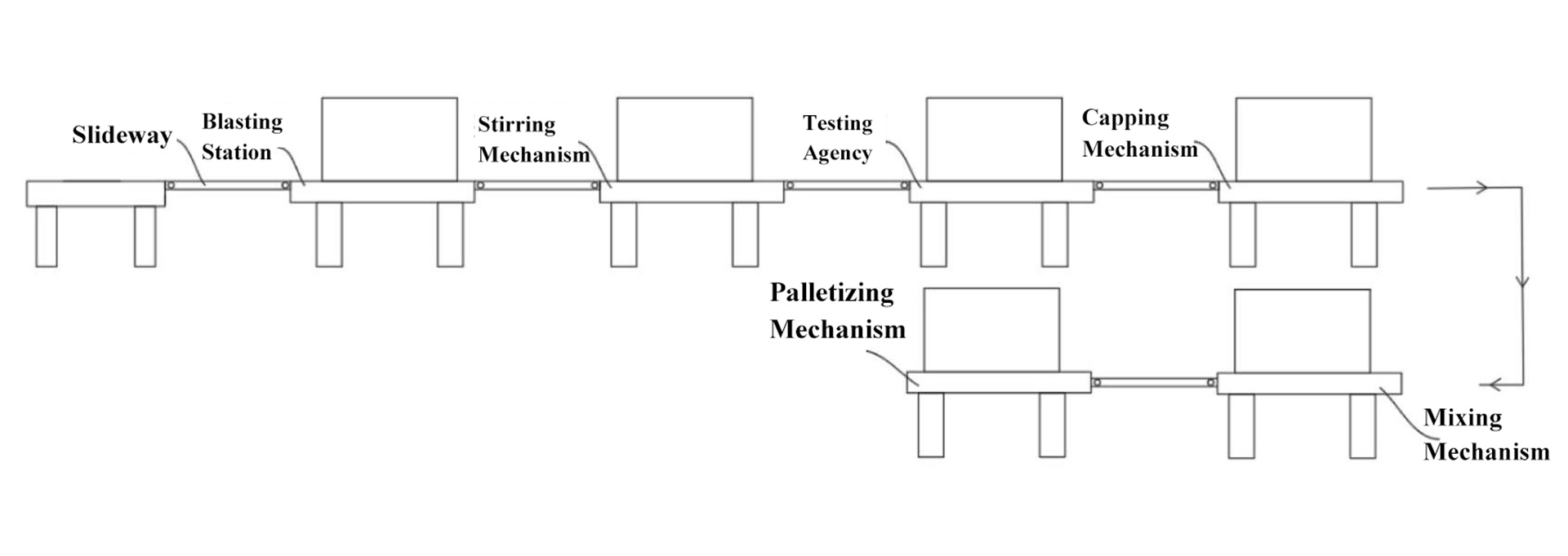

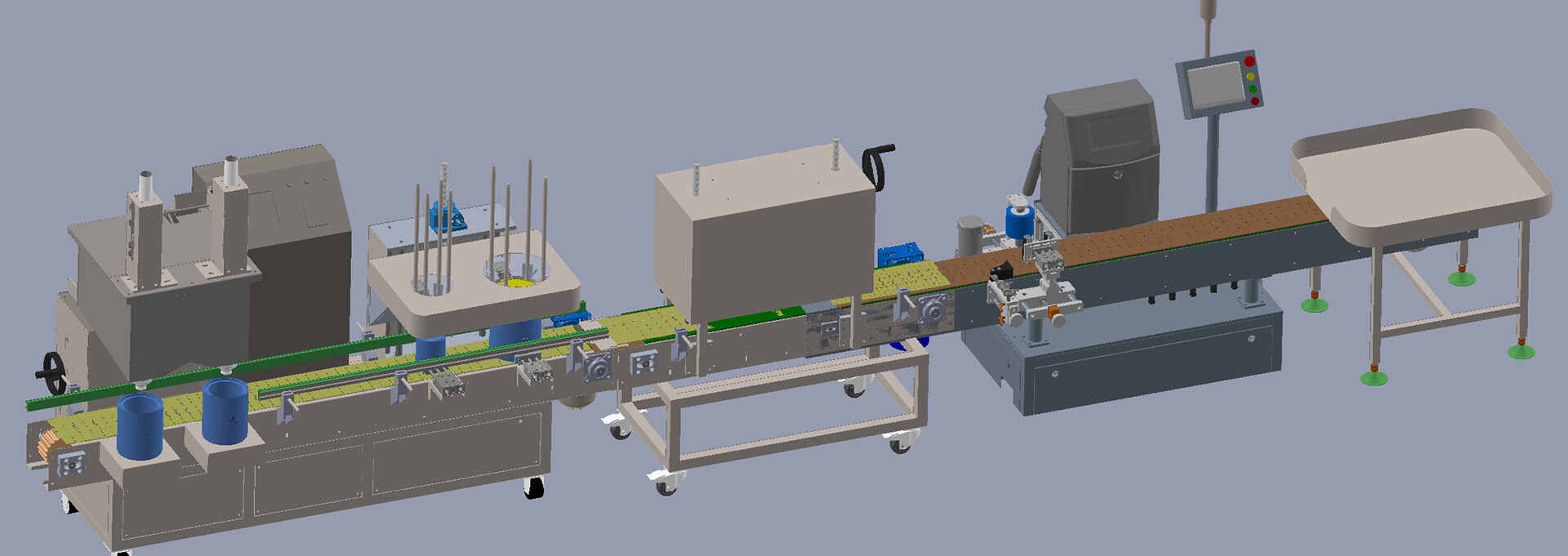

Proprietary rail-guided transport system ensures:

100% contamination-free processing

24/7 continuous operation

30% faster cycle time vs conventional systems

4.Self-Learning Formula Database

Machine learning module continuously improves:

Color matching precision

Viscosity control (±1%)

Batch-to-batch consistency

Operational Advantages:

60% labor cost reductionthrough elimination of manual:

Color matching technicians

Batch adjustment operators

Material handling staff

40% faster order fulfillmentwith intelligent production sequencing

Zero material wastevia precision dosing systems (accuracy to 0.1ml)

Industry Impact:

“This changes the rules of custom coating production,” said Dr. Emily Tan, Senior Analyst at Coatings World. “The autonomous color correction capability particularly disrupts traditional workflows that required master technicians.”