Ⅰ.Limitations of Traditional Filling Equipment

Traditional filling machines, primarily manual or semi-automatic systems, present several significant drawbacks for modern production:

Low Filling Precision: Reliance on operator skill often leads to inconsistent filling volumes and inaccurate flow control. This variability directly compromises product quality and consistency.

Limited Production Capacity: Manual intervention inherently bottlenecks the process. These systems have slower cycle times, resulting in significantly lower output (bottles/hour) that cannot meet high-volume manufacturing demands.

Complex & Labor-Intensive Operation: The workflow is typically a multi-step, repetitive process involving manually transferring the liquid product, followed by separate sealing and labeling stages. This cumbersome handling increases labor requirements and the potential for errors.

Ⅱ.Advances in Modern Filling Technology

Technological developments have driven innovations in filling technology, giving rise to modern filling equipment. Modern filling equipment tackles the limitations of older machines, with key advantages including:

Precision Filling: Precise control of liquid flow and filling volume ensures stable and reliable drug quality.

High production efficiency: Utilizing automated processes, these systems achieve fast filling speeds to meet large-scale production demands; high-end equipment further enhances productivity through intelligent control functions.

Strong operational convenience: Significantly reducing manual intervention, these systems can automatically complete filling, sealing, and labeling processes through parameter settings, thereby significantly saving labor and time.

Ⅲ.Filling Equipment Types: Matching Technology to Your Product

3.1.By Filling Material:

Liquid Filling Machine: Suitable for liquids with good flow ability;

Paste Filling Machine: Suitable for high-viscosity materials;

Powder Filling Machine: Mainly for dry powder products;

Granular Filling Machine: Suitable for granular or small particle materials.

3.2.By Filling Method:

Atmospheric Pressure Filling Machine: Relies on gravity flow, suitable for liquids with good flow ability;

Isobaric Filling Machine: Suitable for gaseous liquids such as carbonated beverages;

Vacuum Filling Machine: Suitable for viscous liquids, helps reduce bubbles;

Piston Filling Machine: Suitable for thick or particulate materials.

3.3.By Automation Levels:

|

Type |

Throughput Range |

Best For |

|

Semi-Automatic |

10-30 CPM |

Startups, R&D batches |

|

Linear Fillers |

30-150 CPM |

Mid-volume cosmetics |

|

Rotary Fillers |

150-600 CPM |

Beverages, pharmaceuticals |

Ⅳ. Double-nozzle liquid filling machine: a practical and efficient liquid packaging solution

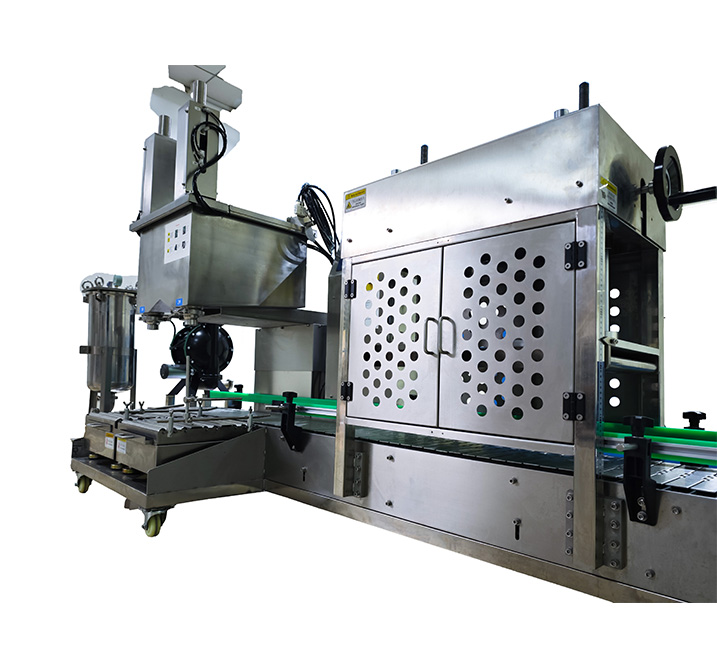

The Double-nozzle liquid filling machine is an automated quantitative filling device. Its most distinctive feature is its Double-nozzle design, enabling simultaneous filling of two containers, significantly enhancing operational efficiency. This equipment is suitable for a wide range of liquid products, from low to high viscosity, catering to industries such as chemicals, coatings, biotechnology, and new energy. It meets the fully automated requirements for products of various specifications and categories.

4.1.Structure of Double-Head Liquid Filling Machines

Twin-head liquid filling machines consist of these core components working together:

Liquid Storage Tank: Holds the product before filling. Some units include integrated mixing or heating systems for material preparation.

Filling Mechanism: Precisely transfers and doses the liquid. Common technologies include piston pumps, peristaltic pumps, gear pumps, or pneumatic cylinder systems.

Double Filling Heads: The key operational units. These nozzles work simultaneously or independently, enabling accurate portion control for consistent fill volumes.

Container Handling System: Often features an integrated conveyor belt for automatic bottle feeding, precise positioning under the fill heads, and ejection after filling.

Control System: Typically utilizes a PLC controller with a user-friendly touchscreen interface (HMI) for easy operation, parameter adjustment, and real-time process monitoring.

Anti-Drip Mechanism: Prevents product spillage and contamination, ensuring clean operation and container exteriors.

4.2.How does a dual-head filling system work?

1.Efficient raw material delivery: Liquid raw materials enter the system via pipelines or directly from integrated storage tanks. The equipment employs reliable feeding mechanisms, such as vacuum suction, pneumatic pressure, or precision piston pump metering, to ensure a stable and continuous supply of liquid to the filling heads.

2.Core: Precise Quantity Filling: This is the key to the equipment’s performance. Depending on the liquid characteristics and precision requirements, the system employs advanced filling technologies such as piston-driven, high-precision flow meters, or gravity flow. Regardless of the method used, the core objective is to ensure that the filling volume of each bottle meets the set standard value, achieving high consistency.

3.Anti-drip control: Intelligent anti-drip functionality eliminates any dripping, keeping the bottle opening clean and free from contamination, thereby ensuring the aesthetic quality of the final product.

4.Efficiency boost: Dual-head synchronized operation. Two filling units work in tandem to simultaneously fill two bottles, doubling production efficiency compared to single-head equipment. This design is particularly suitable for small and medium-sized enterprises to meet bulk production demands and optimize output.

5.Smart control system:Utilizes an advanced PLC control system with an intuitive touchscreen human-machine interface (HMI) for interaction. Operators can easily set key parameters such as filling volume and speed, and flexibly choose between fully automatic continuous operation or semi-automatic single-cycle mode, ensuring precise and convenient control.

6.Conveying and Sealing (Optional): After filling, finished bottles are automatically transported out of the workstation via an integrated conveyor belt system. This system seamlessly integrates with downstream processes such as automatic capping/sealing, labeling, coding, or packaging, forming a complete automated production line to further enhance overall efficiency.

4.3.Dual-head liquid filling machine: Core advantages and outstanding features

The dual-head liquid filling machine is specifically designed to enhance production efficiency and filling accuracy for small to medium-sized batches, combining high efficiency, precision, flexibility, and hygiene into one, making it an ideal choice for modern liquid packaging. Its core features include:

1.Dual-station high-efficiency filling, doubling production capacity

Core advantage: Dual filling heads operate synchronously and precisely, capable of processing two containers simultaneously.

Significant benefits: Production efficiency is approximately 100% higher than single-head equipment, effectively shortening production cycles.

Application scenarios: Perfectly suited for medium-scale production needs, optimizing production capacity utilization and reducing unit costs.

2.High-precision filling, stable and reliable quality

Core technology: Utilizes a high-precision flow meter metering system or a servo-driven piston metering unit.

Performance Guarantee: Filling accuracy error strictly controlled within ±1% (or even higher, depending on configuration).

Core Value: Ensures high consistency in filling volume within and between batches, serving as the foundation for product quality stability.

3.Wide Material Compatibility:

Compatible Liquids: Easily handles water, juice, milk, edible oil, cosmetic lotions/ serums, pharmaceutical solutions, chemical reagents, detergents, disinfectants, and other liquids with varying viscosities and characteristics.

Core Capability: Robust compatibility design enables stable filling of materials ranging from low-viscosity aqueous solutions to medium-to-high-viscosity pastes/lotions.

4.Intelligent Human-Machine Interaction for User-Friendly Operation

Control Core: Equipped with an advanced PLC control system and a high-definition color touchscreen human-machine interface (HMI).

User-friendly operation: Intuitive parameter settings (filling volume, filling speed, interval time, etc.), formula storage and recall functionality.

Flexible adjustment: Easily switch between production tasks, significantly reducing downtime for setup, with simple and intuitive operation.

5.Clean filling with effective drip and foam prevention

Key design: Utilizes a specially structured anti-drip filling valve.

Cleanliness assurance: Automatically cuts off the liquid flow upon lifting at the end of filling, completely eliminating drips and maintaining cleanliness of the bottle opening and surrounding environment.

Special solutions: Integrated anti-foaming technology (such as slow-flow design and liquid level tracking), particularly suitable for liquids prone to foaming (e.g., shampoo, body wash, disinfectant, beer, etc.), ensuring precise filling volume and a clean appearance.

6.High-quality material construction, compliant with stringent hygiene standards

Main Materials: All components in direct contact with the product (such as tanks, pipes, filling valves, and frames) are made of high-quality SUS304 or SUS316L stainless steel.

Core Advantages: Excellent corrosion resistance, ease of cleaning, and rust prevention.

Certification compliance: Strictly adheres to food-grade (GMP), pharmaceutical-grade (if required), and chemical industry hygiene and safety standards to ensure product safety.

7.Excellent container compatibility and flexibility

Easy adjustment: Filling height, bottle mouth positioning mechanism, etc., can be conveniently adjusted.

Wide applicability: Easily adapts to containers of various materials and specifications, including glass bottles, PET plastic bottles, HDPE bottles, metal cans, and tubes of different diameters/heights.

Value proposition: Multi-functional machine that quickly responds to diverse packaging needs, reducing equipment investment.

8.Robust scalability and production line integration capabilities

Open interfaces: Standardized input/output interfaces and mechanical interface design.

Seamless integration: Easily integrates with upstream equipment (e.g., automatic bottle sorting machines) and downstream equipment (e.g., automatic capping/sealing machines, labelers, inkjet printers, case packers, and shrink wrappers).

Future value: Build a complete automated packaging production line, significantly enhance overall production automation levels and efficiency, and reserve space for capacity upgrades.

Ⅴ.Conclusion

Choosing the right liquid filling machine transcends simple equipment selection; it’s a strategic investment in your production efficiency. Success demands a clear grasp of core technologies like volumetric, piston, and gravity filling – their capabilities and ideal applications. By precisely matching this technical landscape to your specific operational needs (liquid characteristics, throughput, precision), you unlock significant gains: streamlined filling processes, elevated productivity, and robust, consistent product quality.

For small to medium-scale producers across chemicals, cosmetics, food & beverage, pharmaceuticals, and biotechnology, the double-head liquid filling machine stands out as a practical, high-performance solution. It masterfully balances exceptional speed with superior accuracy, operational flexibility, and hygienic design, delivering the competitive edge modern manufacturing demands.

However, maximizing your return often requires thinking bigger than a single machine. For businesses aiming for peak operational performance, seamless workflow, and scalable growth, integrating your filling machine into a complete, automatic filling system is the ultimate strategic move.

Ready to Transform Your Liquid Filling Line?

Don’t let outdated equipment limit your potential. Investing in the right filling technology is key to streamlining operations, elevating product quality, and driving sustainable growth.

Identify your specific needs: Consider your liquid characteristics, required throughput (bottles/hour), accuracy tolerance, container types, and hygiene standards.

Evaluate modern solutions: Focus on technologies like precision piston filling, flow meter dosing, and dual-head automation that directly address your challenges.

Partner with experts: Choose a supplier who understands your industry and can provide reliable, high-performance filling equipment.

Take the next step towards optimized production and superior packaging. SIGHTEC offers cutting-edge liquid filling solutions, including high-efficiency double-nozzle machines, designed to meet your exact requirements. Contact us today for a consultation and discover how we can help you achieve peak filling performance.