Shipping Update: Today, a high-performance automatic ink dispensing system left our production facility, beginning its journey to Buenos Aires, Argentina! This delivery represents more than just a fulfilled order. It is another testament to our deep commitment to the South American market. This “Disc-type Ink Dispenser” embodies the latest advancement in ink management technology. In this article, we will explore the technical excellence of this machine and provide a comprehensive guide to navigating logistics from China to South America.

In today’s competitive printing industry, color consistency, production speed, and cost control define successful businesses. Many companies still rely on manual ink mixing. This traditional method creates uncertainty and inefficiency. Modern printing ink dispensing systems offer a smarter solution. Upgrading your equipment transforms your entire production management strategy.

We Solve Your Core Pain Points:

Pain Point 1: Unreliable Color Consistency. Manual weighing often leads to errors. These small mistakes create visible color shifts between print jobs. This inconsistency can damage your brand’s reputation.

Pain Point 2: High Costs from Ink Waste. Hand-mixing is an imprecise process. Leftover ink hardens in containers and on tools. This waste creates a significant, hidden cost that hurts your profitability.

Pain Point 3: Bottlenecks that Slow Production. Matching complex spot colors by hand takes too much time. This delays your entire printing workflow. It prevents you from accepting urgent, short-run orders from clients.

Pain Point 4: Over-Dependence on Skilled Staff. The knowledge of experienced mixers is hard to document and transfer. When a key employee leaves, your production stability and quality control face serious risks.

Our Solution and Key Selling Points:

Our advanced disc-type ink dispensing system is designed to solve these problems. It is a complete productivity solution for color management.

Selling Point 1: Extreme Precision for Perfect Color. The heart of our system is a high-precision dispensing valve. It manages four distinct dosing stages: large, medium, small, and drip-feed. This achieves a remarkable accuracy of 0.1 grams. Combined with a top-tier weighing system, it guarantees perfect recipe replication every time. You can finally eliminate color variation.

Selling Point 2: Reduce Costs by Stopping Waste. Achieving 0.1-gram accuracy maximizes your ink utilization. The system follows the digital recipe exactly, with almost no leftover material. For expensive specialty inks, this saving can quickly pay for the machine itself and directly boost your profit margins.

Selling Point 3: Automate to Multiply Your Efficiency. As a true automatic ink dispensing system, it simplifies operation. Your staff selects a formula in the software. The system then automatically retrieves, weighs, and returns all inks. This frees your master mixer for more critical tasks. It also allows new operators to produce perfect colors easily. You can often multiply your production output.

Selling Point 4: Built for Reliability and Long-Term Use. We build our systems to last. The control center uses an industry-leading PLC for reliable operation. Critical components like pneumatic pumps and weighing modules are sourced from global top-tier manufacturers. This commitment to quality ensures thousands of hours of stable, trouble-free performance in demanding industrial environments.

Section Summary:

Upgrading to a modern printing ink dispensing system is a strategic investment. It directly addresses your biggest challenges in quality, cost, and efficiency. It turns color management from an unpredictable “art” into a precise “science.”

Let’s examine the specific features of the system destined for Argentina. See how we translate our selling points into tangible, high-performance technology.

1. Core Design: An Integrated Disc-Type Workstation

This is not just a single machine. It is a fully integrated workstation. The core is a disc-type gravimetric dispensing machine. It works with a volumetric dispenser, planetary mixer, colorimetric spectrophotometer, and color matching software. The disc-type design is compact and space-efficient. Its ability to hold 12 base inks meets the demands of most spot color applications.

2. Safety First: Comprehensive Explosion-Proof and Static Control

Safety is our top priority in industrial design. This ink dispensing system meets strict explosion-proof standards from the ground up.

Explosion-Proof Control Cabinet: This ensures absolute safety for electrical components, even in environments with flammable ink vapors.

Full Anti-Static Protection: We treat all parts that contact ink with special anti-static materials. This effectively eliminates the fire risk caused by static electricity buildup. It provides a double layer of safety for your workshop.

3. Performance Heart: Premium Components for Unmatched Reliability

We believe long-term stability comes from never compromising on core components.

Control Center: We use a high-performance PLC to ensure reliable and rapid system control.

Precision Sensing: A precision weighing system provides accurate data for 0.1-gram dosing.

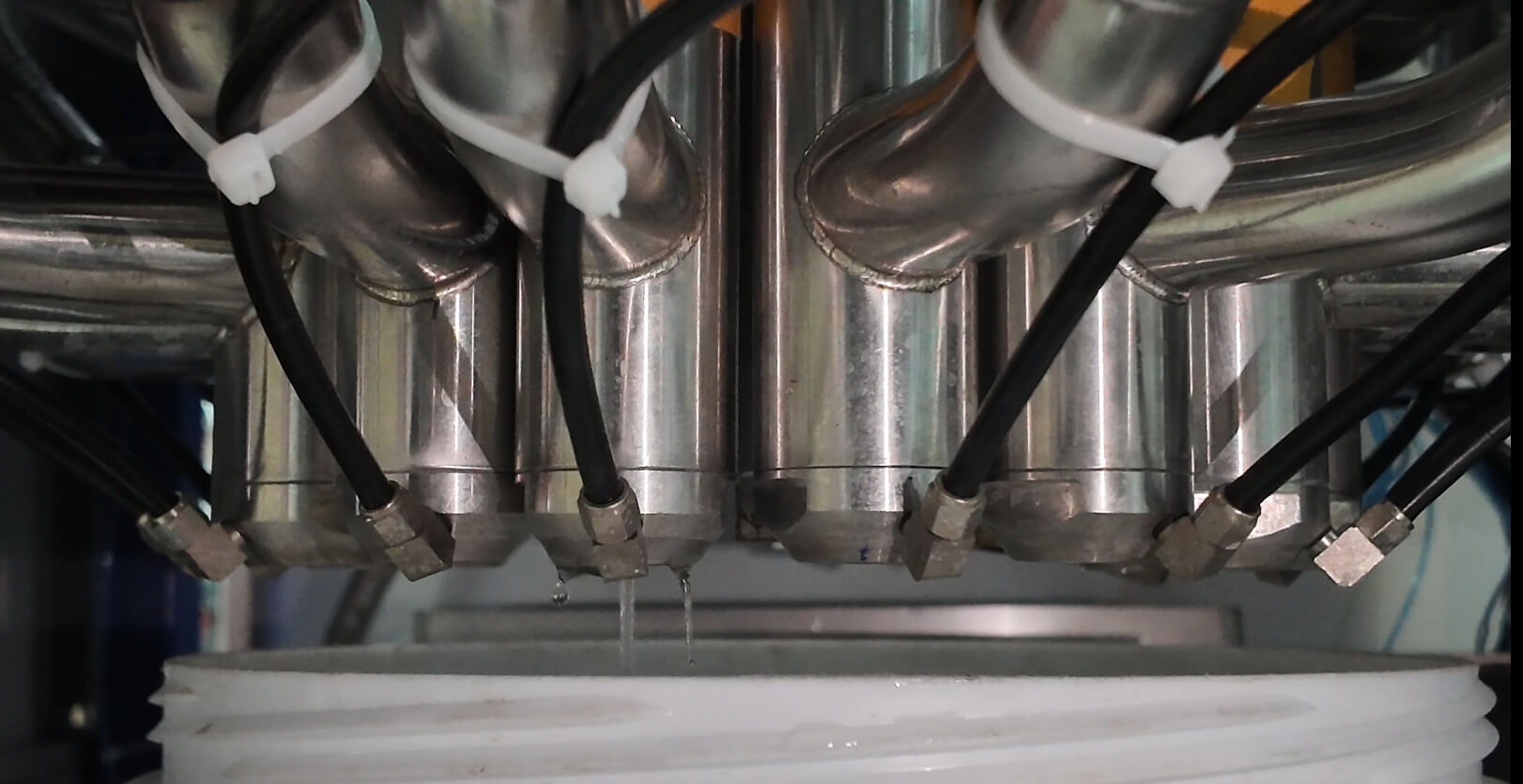

Durable Execution: We use high-performance pneumatic diaphragm pumps and a proprietary, corrosion-resistant dosing valve. This guarantees speed, accuracy, and long-term durability.

4. User Experience: Aesthetic and Easy-to-Maintain Design

We know that excellent industrial design matters. The brushed stainless steel exterior gives the machine a modern, professional look. More importantly, the smooth, seamless surface is incredibly easy to clean and maintain. It prevents ink residue and bacteria growth, helping you maintain a high-standard workshop environment.

Section Summary:

The automatic ink dispensing systems we send to clients in Argentina and worldwide represent a perfect blend of advanced technology, premium materials, and user-friendly design. It is not just a machine; it is an intelligent partner that creates continuous value for your business.

Shipping a precise and valuable piece of equipment like an Ink Dispenser to a distant destination like Argentina is a complex process. It requires far more expertise than standard freight. This is where your choice of supplier becomes critical. The following guide draws from our extensive experience with successful shipments to South America.

Step 1: Pre-Shipment Preparation – Where Professionalism Begins

Professional Custom Crating: For a precision Ink Dispenser, packaging is the first line of defense. We build custom, reinforced wooden crates. Inside, we use anti-vibration padding and moisture-proof materials to secure the equipment. This protects your investment during weeks of ocean transit.

Documentation Review: We prepare all necessary customs documents for you. This includes the commercial invoice, packing list, equipment specifications, and certificate of origin. Accurate paperwork is especially critical for Argentine imports.

Step 2: Choosing the Right Shipping Method – Ocean vs. Air

Ocean Freight (The Cost-Effective Choice): This is the most economical option for large, non-urgent equipment. Shipping from major Chinese ports to Buenos Aires typically takes 35-45 days. We provide both full container load (FCL) and less than container load (LCL) services.

Air Freight (The Speedy Alternative): This is much faster, usually taking 3-7 days. However, it costs significantly more. It is best for critical machinery that is needed urgently.

Step 3: Mastering South American Customs – Experience Matters

South American countries, particularly Argentina, are known for their complex customs and tax policies.

Focus on Argentina:

Import Licenses: Certain products may require an advance license.

Foreign Exchange Controls: Payment routes must comply with central bank regulations.

Taxes and Duties: Be prepared for import duties, value-added tax (VAT), and other statistical fees.

How We Help: We act as your logistics partner. Our extensive experience in South American exports allows us to identify risks early. We help you or your importer prepare the correct documents for local customs. We can also recommend reliable local agents to ensure your Ink Dispenser clears customs smoothly, avoiding costly port delays.

Step 4: Final Delivery and Setup Support

Once customs clear the goods, we can coordinate with local partners to deliver the system safely to your factory. We also provide professional remote guidance for installation and calibration. This ensures your new equipment gets up and running quickly.

Section Summary:

Successfully delivering an Ink Dispenser to South America is a complex process. It involves international shipping, customs regulations, and local practices. Choosing a partner with a proven track record and mature processes is your safest strategy to minimize risk, control costs, and ensure a smooth startup.

The disc-type automatic ink dispensing systems we shipped to Argentina today is a powerful example of our capabilities. We deliver more than a world-class machine. We provide a complete, start-to-finish solution that includes professional consultation, custom engineering, quality production, international logistics, and customs support.

We understand that investing in a new printing ink dispensing system is a major decision. Your concerns go beyond machine performance. You need to know it will arrive safely and become a reliable part of your production line.

We give you that confidence.

Our production and logistics teams are constantly in motion. The next Ink Dispenser destined for South America could be yours.

Don’t wait. Take the next step today:

1. Contact Us for a Detailed Quote: Receive full technical specifications and a competitive price for our disc-type dispensing system.

2. Get a Custom Logistics Plan: Describe your needs and receive a tailored shipping quote to your city in South America.

3 . Download Our Product Brochure: Get detailed specifications and see the full range of our ink dispensing solutions.

Let our expertise become your competitive advantage in the global market. We look forward to hearing from you!