In today’s highly competitive printing industry, color accuracy has evolved from a “nice-to-have” feature to an absolute necessity. Printers and their clients depend on consistent, reliable color matching across every project, from corporate branding materials to packaging and publications. While printing technology has advanced significantly over the past decade, achieving perfect color reproduction remains challenging. The consequences of poor color management extend beyond mere aesthetics, directly impacting brand integrity, customer trust, and ultimately, business profitability.

Color management represents both a technical discipline and a strategic business approach. It encompasses everything from initial equipment calibration to ongoing process control and quality assurance. When implemented effectively, a robust color management system can significantly reduce waste, improve efficiency, and enhance customer satisfaction. This comprehensive guide explores the essential components of color management, providing practical strategies for maintaining color excellence in printing operations of all sizes and specialties.

Color management begins with understanding how humans perceive color. The human eye contains specialized receptors called cones that respond to different wavelengths of light. This biological foundation means that color perception is inherently subjective, influenced by lighting conditions, surrounding colors, and individual physiological differences. In printing, we must translate this subjective experience into objective, measurable parameters.

The science of color measurement relies on standardized systems that quantify color in numerical terms. The CIE Lab color space, developed by the International Commission on Illumination, provides a comprehensive framework for defining color regardless of the output device. This system enables printers to communicate color specifications accurately and consistently across different media and printing technologies.

The commercial implications of color management extend far beyond the pressroom. For brand owners, color consistency is non-negotiable. Research shows that color increases brand recognition by up to 80%, and consistent color presentation across all materials strengthens brand identity and consumer trust. When packaging colors vary between production runs, consumers may perceive the product as counterfeit or of inferior quality.

From an operational perspective, effective color management directly impacts profitability. The time spent correcting color issues, reprinting jobs, and dealing with customer complaints represents significant costs. Industry studies indicate that poor color management can increase waste by 15-20% and reduce overall equipment effectiveness by similar margins. Conversely, operations with robust color management systems report faster job turnaround, reduced material consumption, and higher customer retention rates.

Calibration forms the foundation of any effective color management system. At its core, calibration is the process of adjusting printing equipment to produce colors according to specified standards. This process ensures that your presses, proofers, and other output devices operate within defined parameters, creating a predictable, repeatable color reproduction environment.

The calibration process involves multiple stages, beginning with characterizing the device’s natural color behavior. This characterization establishes a baseline profile that shows how the device reproduces color without intervention. Using this information, technicians can then adjust the device to align with industry standards or custom specifications. The final step involves verifying the calibration and documenting the results for future reference.

Successful calibration requires careful planning and execution. Begin by establishing clear calibration standards based on your specific printing processes and customer requirements. Common industry standards include ISO 12647 for process color printing and G7 methodology for gray balance calibration. These standards provide specific targets for dot gain, density, and color balance, ensuring consistent results across various devices and substrates.

The calibration process typically involves printing and measuring a standardized test target containing various color patches. Specialized software analyzes the measurements and generates correction curves that adjust the device’s output to match the desired standards. Modern systems often automate this process, but human oversight remains essential for verifying results and addressing any anomalies.

Regular calibration scheduling is crucial for maintaining color accuracy. The frequency of calibration depends on several factors, including equipment stability, environmental conditions, and quality requirements. High-precision printing operations may require daily calibration, while less critical applications might maintain adequate control with weekly or monthly intervals. Documenting each calibration session creates valuable historical data for tracking equipment performance over time.

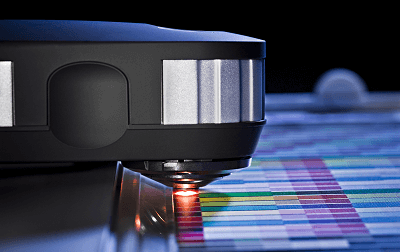

Modern calibration relies on sophisticated measurement instruments, primarily spectrophotometers and densitometers. Spectrophotometers provide the most comprehensive color data by measuring spectral reflectance across the visible light spectrum. This detailed information enables precise color characterization and supports advanced color management workflows.

When selecting measurement instruments, consider factors such as measurement geometry, inter-instrument agreement, and compatibility with your existing systems. Modern devices often feature automated scanning capabilities, polarized filters for measuring wet inks, and integrated temperature compensation for improved accuracy. Regular instrument calibration against certified standards ensures measurement consistency over time.

Advanced calibration systems integrate seamlessly with digital workflows, automating much of the calibration process. These systems typically include software that manages calibration targets, analyzes measurement data, and generates correction curves. Integration with production workflow systems enables automatic profile updates and ensures that all production elements use consistent color settings.

Cloud-based color management systems represent the latest advancement in calibration technology. These platforms centralize color data from multiple locations, enabling standardized calibration across distributed printing operations. They provide real-time monitoring of color performance and automated alerts when devices drift outside established tolerances.

Even perfectly calibrated printing systems experience color drift over time. This gradual deviation from established color standards stems from multiple factors, each requiring different control strategies. Understanding these causes is the first step in developing effective process control measures.

Mechanical wear represents a significant cause of color variation in conventional printing presses. As rollers, blankets, and bearings wear, they affect ink transfer and pressure consistency. In digital printing systems, component aging in imaging units, fusers, and paper transport mechanisms similarly impacts color reproduction. Environmental factors, including temperature, humidity, and air quality also influence color output, particularly in water-based and solvent-based printing processes.

Material variations constitute another major source of color inconsistency. Substrates from different production batches often exhibit slight differences in whiteness, brightness, and surface characteristics that affect color appearance. Similarly, variations in ink formulation, viscosity, and pigment concentration can lead to noticeable color shifts. Implementing rigorous material testing and qualification procedures helps minimize these variations.

Effective process control requires defining specific parameters that indicate process stability. These typically include density, dot gain, gray balance, and trapping values for conventional printing, while digital processes may focus on linearization, color uniformity, and mottle prevention. Establishing realistic tolerances for each parameter ensures that control measures focus on meaningful variations rather than insignificant fluctuations.

Statistical process control (SPC) methodologies provide powerful tools for monitoring printing processes. Control charts track key parameters over time, distinguishing between normal process variation and significant deviations requiring intervention. Modern workflow systems often include integrated SPC capabilities, automatically collecting measurement data and generating control charts in real-time.

A successful process control system combines regular measurement with clear response protocols. The frequency of process verification depends on the printing technology, job requirements, and historical process stability. High-volume production environments typically implement continuous monitoring using automated scanning systems, while smaller operations may rely on periodic manual measurements.

Control procedures should specify exactly what to measure, when to measure, and how to respond to out-of-tolerance conditions. This includes defining measurement locations on the sheet, specifying the number of sheets to measure, and establishing averaging protocols where appropriate. Response protocols should outline escalation procedures, correction methods, and verification requirements after making adjustments.

Modern printing facilities increasingly rely on automated process control systems to maintain color consistency. These systems typically incorporate inline or near-line measurement devices that monitor color bars on every sheet or at regular intervals. Advanced systems can automatically adjust ink keys, register settings, and other press parameters to maintain color within specified tolerances.

The benefits of automated process control extend beyond labor reduction. Automated systems provide more frequent measurements than manual methods, enabling faster detection of color drift. They eliminate human variability in measurement technique and interpretation, ensuring consistent application of control standards. Perhaps most importantly, they enable real-time correction, preventing the production of non-conforming product between manual checks.

Closed-loop control represents the pinnacle of automated color management. These systems continuously measure color output, compare it to established targets, and automatically make press adjustments to maintain color consistency. Unlike open-loop systems that require operator intervention, closed-loop systems self-correct without interrupting production.

The implementation of closed-loop control necessitates substantial investments in measurement technology, control software, and press automation capabilities. However, the return on investment can be substantial through reduced waste, decreased makeready times, and improved color consistency. Modern closed-loop systems incorporate machine learning algorithms that optimize press performance based on historical data, continually improving their correction accuracy over time.

For maximum effectiveness, process control should integrate with broader quality management systems. This integration ensures that color management aligns with overall quality objectives and customer requirements. Quality management frameworks such as ISO 9001 provide structured approaches for documenting procedures, tracking performance metrics, and implementing continuous improvement.

Integrated systems typically include centralized databases that store color measurement data alongside other quality metrics. This comprehensive data collection enables correlation analysis between color performance and other process variables, helping identify root causes of color variation. It also supports trend analysis and predictive maintenance scheduling, addressing potential color issues before they affect production.

The foundation of effective color management lies in accurate, consistent measurement. Modern printing operations utilize various measurement technologies, each suited to different applications and accuracy requirements. Understanding the capabilities and limitations of each technology is essential for selecting appropriate instruments.

Spectrophotometers provide the most comprehensive color data, measuring spectral reflectance across the visible light spectrum. This detailed information supports advanced color management applications including spectral color matching and metamerism evaluation. Densitometers, while less comprehensive, provide reliable measurement of density, dot gain, and trapping for process control in conventional printing.

When selecting measurement instruments, consider factors such as measurement geometry, inter-instrument agreement, and measurement repeatability. Modern instruments often feature automated scanning capabilities, integrated temperature compensation, and support for multiple measurement modes. Regular calibration against certified reference standards ensures measurement accuracy over time.

A consistent measurement technique is crucial for reliable color data. Standardized measurement procedures should specify instrument calibration frequency, measurement geometry, and sample preparation methods. Environmental conditions including lighting, temperature, and humidity, should be controlled to minimize their impact on measurement results.

For reflective measurements, ensure samples are clean, flat, and backed by a standard backing material. Measure multiple locations on printed samples to account for within-sheet variation, and average the results for process control purposes. Establish regular inter-instrument agreement checks to ensure consistency between multiple measurement devices in your facility.

Effective color management requires clear, achievable color standards that align with your printing capabilities and customer expectations. Internal standards should define acceptable color variation, specified in measurable terms using delta E metrics or similar quantitative measures. These standards should balance customer expectations with practical printing limitations.

When establishing color standards, consider the specific requirements of different printing processes and substrates. The same target values may produce different visual results on coated versus uncoated papers, or in offset versus digital printing. Developing substrate-specific standards ensures consistent visual appearance across different media types.

Industry standards provide common frameworks for color communication and reproduction. Widely adopted standards include ISO 12647 for process color printing, G7 for gray balance calibration, and FOGRA for characterization data. Implementing these standards facilitates color consistency across different printing facilities and ensures compatibility with customer color expectations.

Third-party certification programs such as G7 Master, ISO 12647 certification, and Ugra Certified Process Standard provide independent verification of color management capabilities. These certifications demonstrate color management proficiency to customers and can provide competitive advantage in markets where color accuracy is particularly important.

Effective color management requires trained personnel who understand both the technical and practical aspects of color reproduction. Training programs should cover color theory, measurement techniques, equipment operation, and troubleshooting methodologies. Both classroom instruction and hands-on practice are essential for developing comprehensive color management skills.

Certification programs from organizations such as IDEAlliance, FOGRA, and printing associations provide structured training paths and recognized credentials. These programs typically include both theoretical knowledge assessment and practical skill demonstration, ensuring that certified individuals possess both knowledge and application capabilities.

Beyond technical training, successful color management requires organizational commitment to color quality. This begins with clear communication of color quality standards and their importance to customer satisfaction and business success. Regular performance reviews and quality metrics reporting help maintain organizational focus on color consistency.

Cross-functional color teams comprising representatives from prepress, pressroom, and quality assurance help ensure consistent color management across departmental boundaries. These teams can develop standardized procedures, resolve color-related issues, and drive continuous improvement initiatives. Regular inter-departmental meetings facilitate communication about color challenges and collaborative problem-solving.

Continuous improvement begins with comprehensive data collection and analysis. Modern color management systems generate substantial measurement data that, when properly analyzed, provides insights into process performance and improvement opportunities. Statistical analysis of this data helps identify variation patterns, correlate color performance with other process variables, and quantify improvement initiatives’ effectiveness.

Key performance indicators for color management include color consistency metrics, makeready waste percentages, and color-related customer complaints. Tracking these metrics over time provides objective evidence of improvement and helps prioritize initiatives based on their potential impact. Benchmarking against industry standards or similar operations provides context for performance evaluation.

Structured improvement methodologies such as Six Sigma, Lean Manufacturing, and PDCA (Plan-Do-Check-Act) provide frameworks for identifying and implementing color management improvements. These methodologies emphasize data-driven decision making, root cause analysis, and verification of improvement effectiveness.

Color management improvement projects often focus on reducing variation sources, optimizing process parameters, or implementing new technologies. Successful projects typically begin with careful planning, including clear objective definition, stakeholder identification, and resource allocation. Regular progress reviews and objective success measurement ensure that improvement initiatives deliver tangible results.

Color management continues to evolve, driven by technological advancements and changing market requirements. Artificial intelligence and machine learning are increasingly applied to color management, enabling predictive color control and automated optimization. These technologies can analyze historical color data to predict and prevent color variation before it occurs.

Cloud-based color management platforms represent another significant trend, enabling centralized color control across distributed printing operations. These platforms facilitate standardized color implementation, provide real-time performance monitoring, and support collaborative color development between printers and their customers.

As printing technologies evolve, color management must adapt to new challenges and opportunities. The growing importance of customized and personalized printing requires color management systems capable of handling shorter run lengths and more frequent substrate changes. The integration of printing with other manufacturing processes demands color management that extends beyond traditional printing boundaries.

Environmental considerations are increasingly influencing color management practices, with growing emphasis on reducing waste and minimizing environmental impact. This includes optimizing ink usage, reducing energy consumption, and implementing more sustainable color management practices. Printers who proactively address these considerations position themselves for long-term success in evolving markets.

Robust color management requires systematic approach combining appropriate technology, standardized procedures, and trained personnel. The journey toward color management excellence begins with honest assessment of current capabilities and clear definition of improvement objectives. From this foundation, organizations can develop and implement comprehensive color management systems that deliver consistent, predictable color reproduction.

The benefits of effective color management extend far beyond color consistency. Organizations with mature color management capabilities typically experience reduced waste, improved efficiency, enhanced customer satisfaction, and stronger competitive positioning. While achieving these benefits requires significant investment in time, resources, and organizational commitment, the return on investment justifies the effort through improved profitability and business sustainability.

Color management represents both a technical discipline and a business strategy. By embracing both aspects and implementing the principles outlined in this guide, printing organizations can transform color management from a source of frustration to a competitive advantage. The path to color management excellence requires persistence and continuous improvement, but the rewards make the journey worthwhile.