I. Complexity and Challenges of Ink Production Management

Ink manufacturing management is a highly complex system engineering, each stage of which is accompanied by unique control difficulties:

Precision challenge of raw material procurement: The composition of ink raw materials is diverse, and the requirements for quality specifications are extremely stringent. Pigment color purity, resin viscosity, curing characteristics and other subtle differences directly affect the performance of the finished product. Procurement mismanagement can easily lead to raw material outages, inventory redundancy, or specification mismatches, driving up costs and delaying production.

The core control of the formulation process: the formula is the core technical asset that determines the performance of the ink. Different application scenarios require customized formulas, involving precise design of raw material ratios, mixing sequences and reaction conditions. In mass production, it is critical to ensure that the formulation is executed with zero error, as any deviation may lead to the failure of the entire batch.

Precise control of the production process: All aspects of ink production rely on strict control of process parameters. Small fluctuations in temperature, pressure, mixing rate and other parameters can compromise final quality. At the same time, optimizing process connections to maintain efficient, smooth line operations and avoid bottlenecks is an ongoing management challenge.

Quality Assurance and Scientific Storage and Transportation: Finished inks need to pass strict quality checks covering color, viscosity, dryness, adhesion and other dimensions before release. Warehousing requires the implementation of refined management based on ink type, batch, shelf life and other key attributes, the establishment of a scientific storage program to eliminate confusion and the risk of quality change.

Ⅱ. Outstanding Advantages Of Ink Management Software

Greatly improve color matching efficiency and speed:

Instead of tedious manual calculation: Based on a huge basic ink database and advanced algorithms, the software can calculate a formula close to the target color within seconds to minutes, completely getting rid of the inefficient mode of relying on the experience of masters and repeated trial and error.

Quick retrieval of historical recipes: Powerful database management function, which can store and quickly retrieve historical successful recipes and customer spot color recipes, avoiding duplication of effort.

Significantly reduce ink costs:

Reduce waste of trial and error: Accurate initial recipe prediction greatly reduces ink, substrate and labor costs consumed by repeated proofing and debugging.

Optimize formula cost: The software can consider the cost factors of different inks, and automatically calculate or recommend an alternative formula with lower cost on the premise of meeting color requirements.

Precise control of dosage: The calculated formulation is accurate to the gram or milliliter, reducing waste caused by excessive ink dispensing.

Improve color matching accuracy and consistency:

Instrument-based measurement: The core input of the software is the target color standard data and basic ink data measured by the spectrophotometer, which eliminates the subjective error and environmental impact of human eye judgment.

Accurate prediction and correction: Using complex color models and algorithms, it can predict the color after mixing ink with different concentrations with high accuracy, and can intelligently correct and calculate the deviation between the initial proofing and the target to obtain an accurate formula quickly.

Batch-to-batch consistency: Ensure that the same spot color produced at different times, different operators, and different batches is highly consistent, meeting the strict requirements of brand color management.

Color difference calculation and judgment: Automatically calculate the color difference between the matched color and the standard color, and judge whether it is qualified according to the preset standard.

Reduce dependence on senior color matching masters:

The software digitizes and standardizes color matching knowledge and experience, so that operators with relatively little experience can complete high-precision color matching work under the guidance of the software, solving the problem of talent shortage and inheritance.

Support color management and supply chain collaboration:

The generated digital recipes and color data are easily shared and passed across supply chains, promoting more efficient color communication and consistency.

Ⅲ. Core Technology Of Sightec Print Management Software

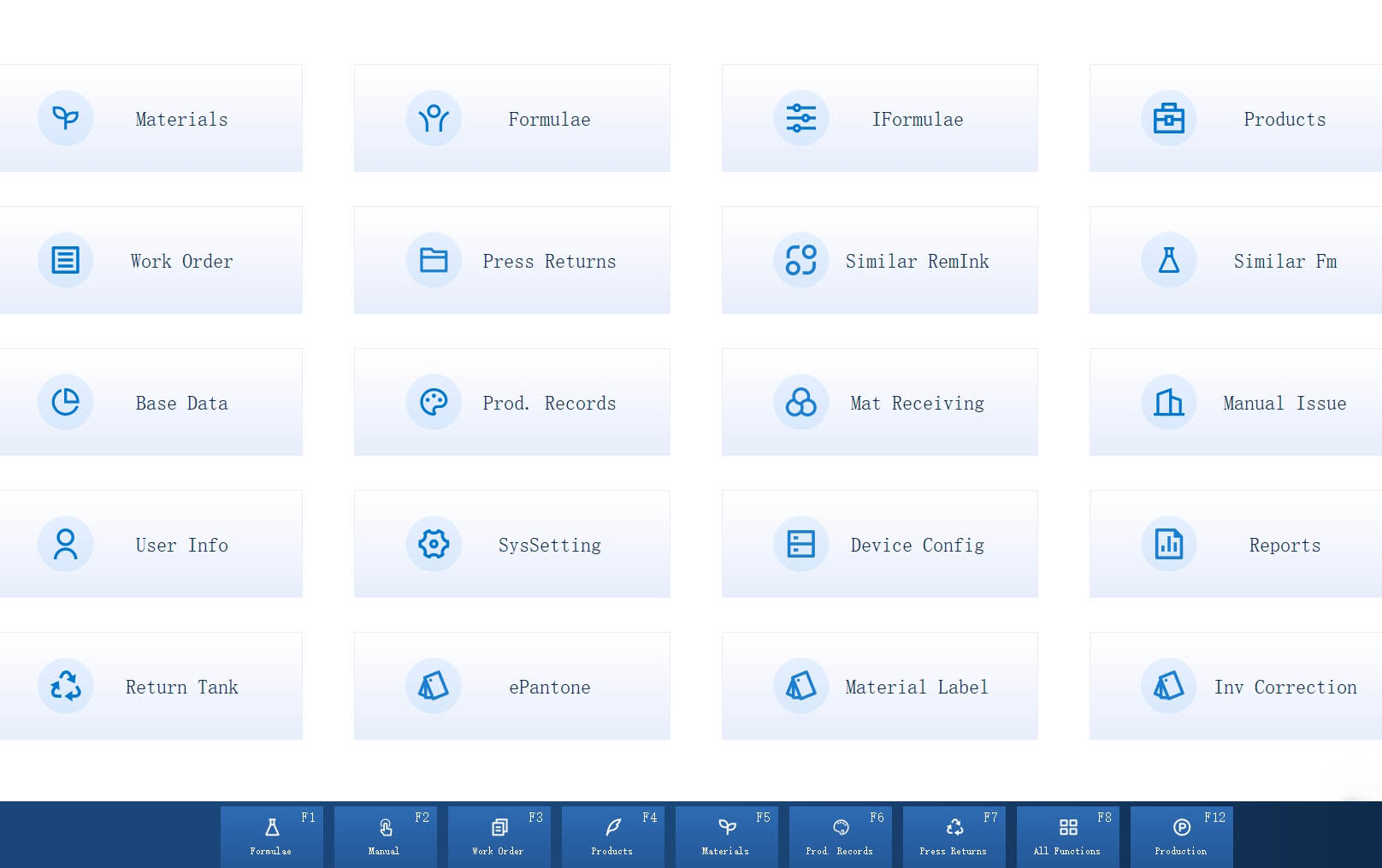

1. Full-Process Digital Management

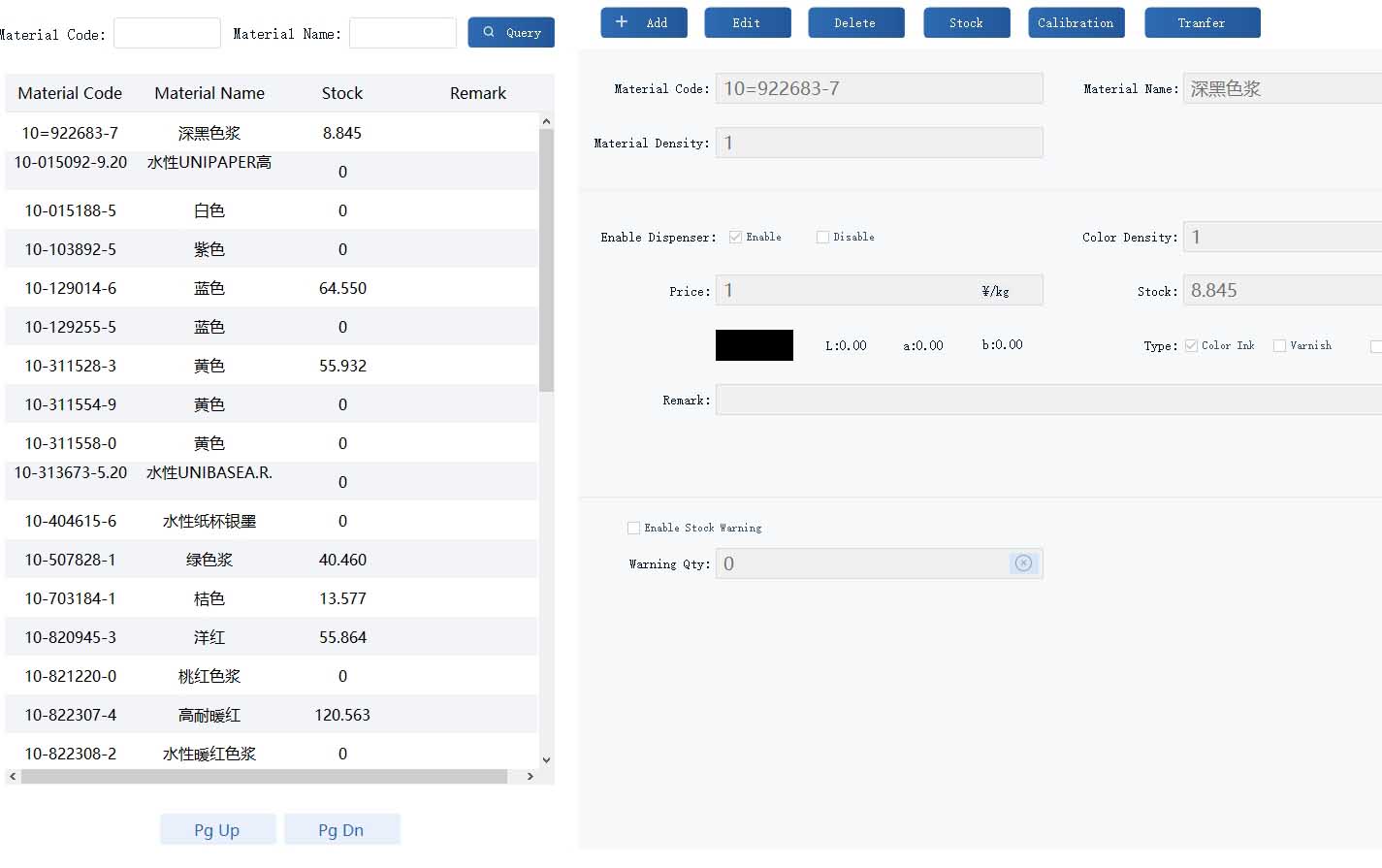

Raw material management: Supports raw material information entry, dynamic inventory tracking (including code scanning for delivery), and inspection card management (customization of inspection items) to ensure accurate and controllable raw material data.

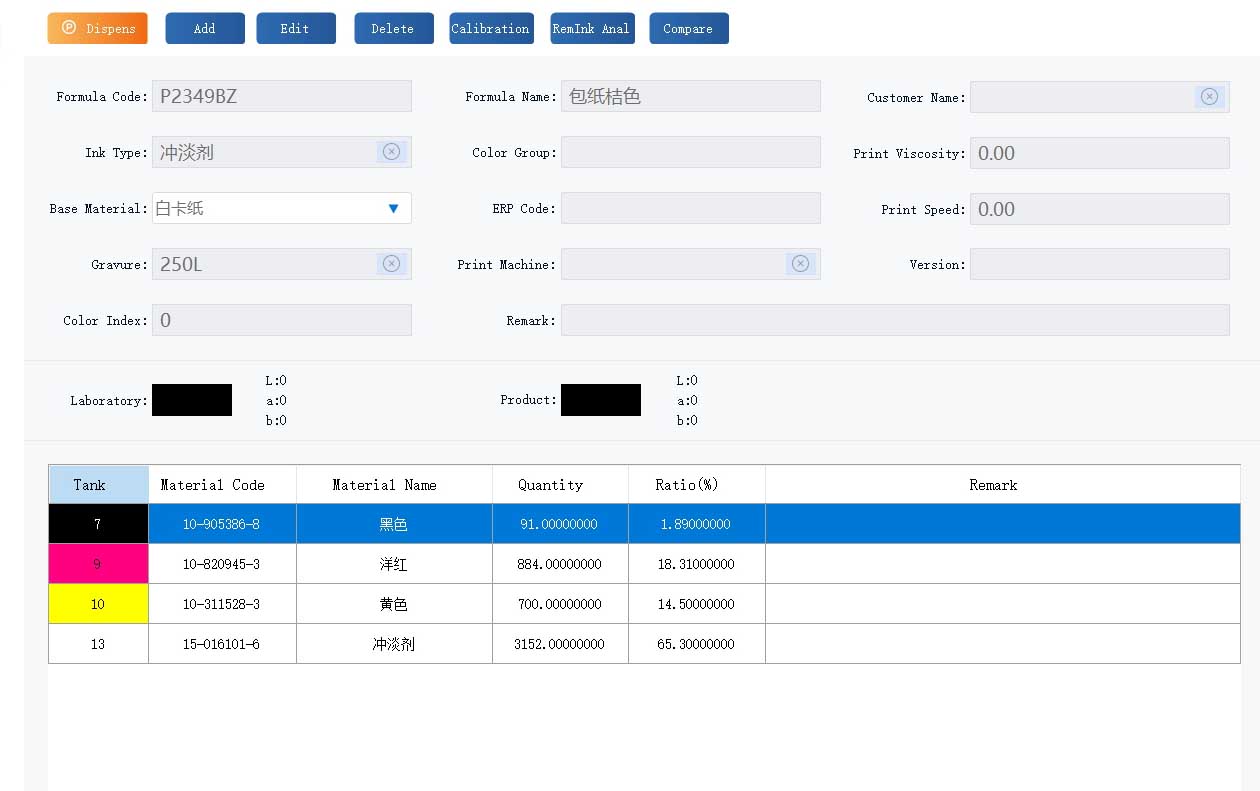

Recipe management: The entire process of recipe creation, editing, and deletion is electronic, supporting “similar recipes” spectral matching retrieval to improve color matching efficiency.

Ink return management: residual ink recovery, spectrum measurement, and inventory adjustment are integrated to significantly reduce ink waste.

2. Intelligent Color Matching And Cost Optimization

Residual ink retrieval function: Automatically analyze the available residual ink through color matching algorithm (similar color calculation) to reduce the use of new ink.

Recycling barrel function: Manually mix residual ink to standard colors, automatically deduct the amount of work orders, and maximize the utilization rate of residual ink.

Work order consumption accounting: accurately count raw material consumption and support cost analysis.

3. Production Automation Collaboration

Work order scheduling linkage: The work order directly drives the production of the color mixing machine, and clicking the “Color Mixing” button will trigger the operation of the equipment.

Color mixing record traceability: records the details of each color mixing (formula, work order, time), and supports label printing and quality traceability

4. Refine Quality Control

Inspection card system: raw materials and formulas are associated with custom inspection items (such as color and viscosity) to ensure quality compliance.

Spectrometer integration: Color measurement data is directly used for formula matching, eliminating human eye errors.

5. Multi-Dimensional Data Integration

Basic data management: Unified maintenance of production factors such as customers, suppliers, and printing presses to ensure data consistency.

Report management: Generate reports such as raw material consumption and finished product statistics with one click, and support Excel export.

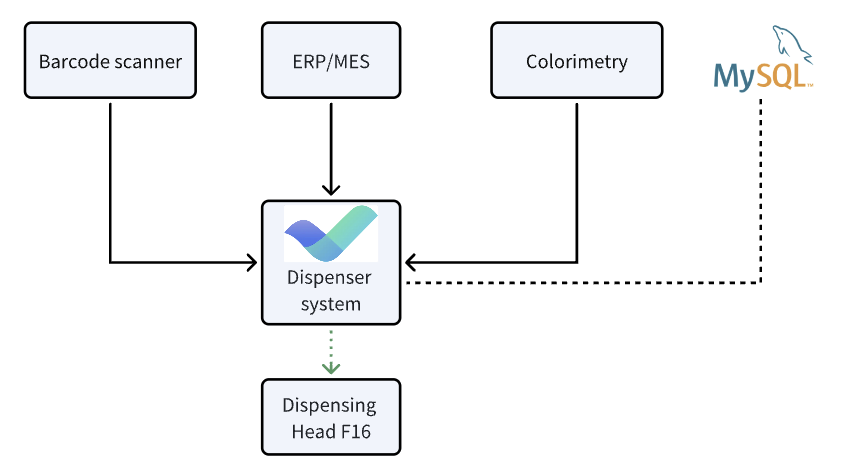

Ⅳ.How The Ink Matching Software Works In Conjunction With The Fully Automatic Color Matching Machine

The linkage between ink matching software and fully automatic color tinting machine realizes a fully automated closed loop from “formula calculation” to “accurate ink output”. Ink color tinting software and fully auto dispenser are the key combinations to achieve efficient, accurate and standardized color production in modern printing, coatings, plastics and other industries. Together, they form the core of a digital and automated color management system. The workflow is described in detail below as follows:

Get target color data:

Users measure the color card or standard sample provided by customers using a spectrophotometer to obtain their color data.

Software calculation recipe:

The operator selects the target color data, the type of substrate to be used, and the base ink library available in the ink dispensing software.

The software calculates according to the built-in color model, the optical characteristics data of the base ink.

The software quickly outputs one or more predicted recipes containing precise weight or volume percentage/absolute values for each base ink.

Recipe transfer to toner:

Critical Interfaces: The ink dispensing software directly and seamlessly transmits the calculated precise recipe to the connected fully automatic color mixer control system via standard communication protocols or dedicated API/drive interfaces. This is the core step of linkage, which avoids possible errors caused by manual input of recipes.

Fully automatic color mixing machine performs ingredients:

The toner control system receives the recipe instruction.

System automatic control:

Select Tank/Barrel: Navigate to the tank for each base ink specified in the recipe.

Accurate Weighing/Metering: Using high-precision weight sensors (gravity type) or volumetric metering pumps (volumetric type), each base ink is precisely drawn or dispensed into the toning tank (main container) according to the formulation requirements.

Sequence control: The viscosity of the ink and the sequence of addition are usually considered, and sometimes it is added while stirring.

Mix and stir:

After all the basic inks are added, the color mixing machine automatically starts the stirring device to fully mix the inks evenly to form the final color matching ink.

Automated quality control closed loop:

Advanced linkage: In some highly integrated systems, the mixed ink can be automatically or semi-automatically made into standardized color samples.

Automatic measurement: The color sample is automatically or manually placed on a spectrophotometer connected to the software for measurement.

Automatic comparison and correction: The measurement data is automatically transmitted back to the ink dispensing software. The software compares the measurement results with the original target standard and calculates the excellence and difference.

If the color difference is within the preset tolerance range, the formula is qualified and the process is finished. This successful recipe is usually automatically deposited into the database.

If the color difference exceeds the range, the software automatically starts the correction calculation function to generate one or more correction formulas (what kind of ink needs to be added and how much).

The corrected recipe is again automatically sent to the toner, which performs micro-addition and re-blending.

This process can be cycled until the color reaches the standard. The software will record each correction process.