Achieving consistent and accurate color is a critical challenge in printing and design. While digital printing often relies on CMYK process colors, spot colors remain the gold standard for brand integrity, vibrant hues, and special effects. This guide provides a comprehensive, professional workflow for managing spot colors from initial selection to final, stable output.

A spot color, also known as a solid color, is a pre-mixed ink that is printed using a single plate, rather than being created through a combination of CMYK dots. This method delivers superior color consistency, a wider color gamut for certain hues, and the ability to use specialty inks like metallics and fluorescents.

The industry relies on standardized color-matching systems. These systems provide numbered color guides with precise ink mixing formulas for different paper stocks, such as coated (C) or uncoated (U).

Key Considerations for Using Color Guides:

Choose the Right Guide: Always use a guide that matches your final printing paper type. The same color will look different on coated versus uncoated paper.

Never Trust Your Screen: Digital monitors cannot accurately replicate the physical ink color. A visual check against a physical guide is non-negotiable for critical color work.

Control Your Viewing Environment: Always check colors under standardized, consistent lighting to avoid metamerism, where colors shift under different light sources.

Pain Point: Relying on a digital mockup or the wrong physical color guide is a primary cause of color disappointment in final products.

Bringing a physical ink color into a digital workflow is a fundamental challenge. Robust digital management prevents errors and streamlines the entire process.

Inconsistency in naming is a major source of error. Digital workflow systems often treat “Brand_Blue” and “brand_blue” as two separate colors.

Best Practices for Naming:

Develop a clear, logical naming structure that is easy for everyone in the supply chain to follow.

Include information like the base hue or the project it’s used for.

Enforce this naming convention across all teams and partners.

A central color library acts as the single source of truth for all color data within your organization or project.

Why You Need a Central Library:

Ensures Consistency: Everyone from designer to printer references the exact same color data.

Boosts Efficiency: Eliminates time wasted searching for or recreating color definitions.

Reduces Errors: Standardization prevents the use of incorrect or outdated color values.

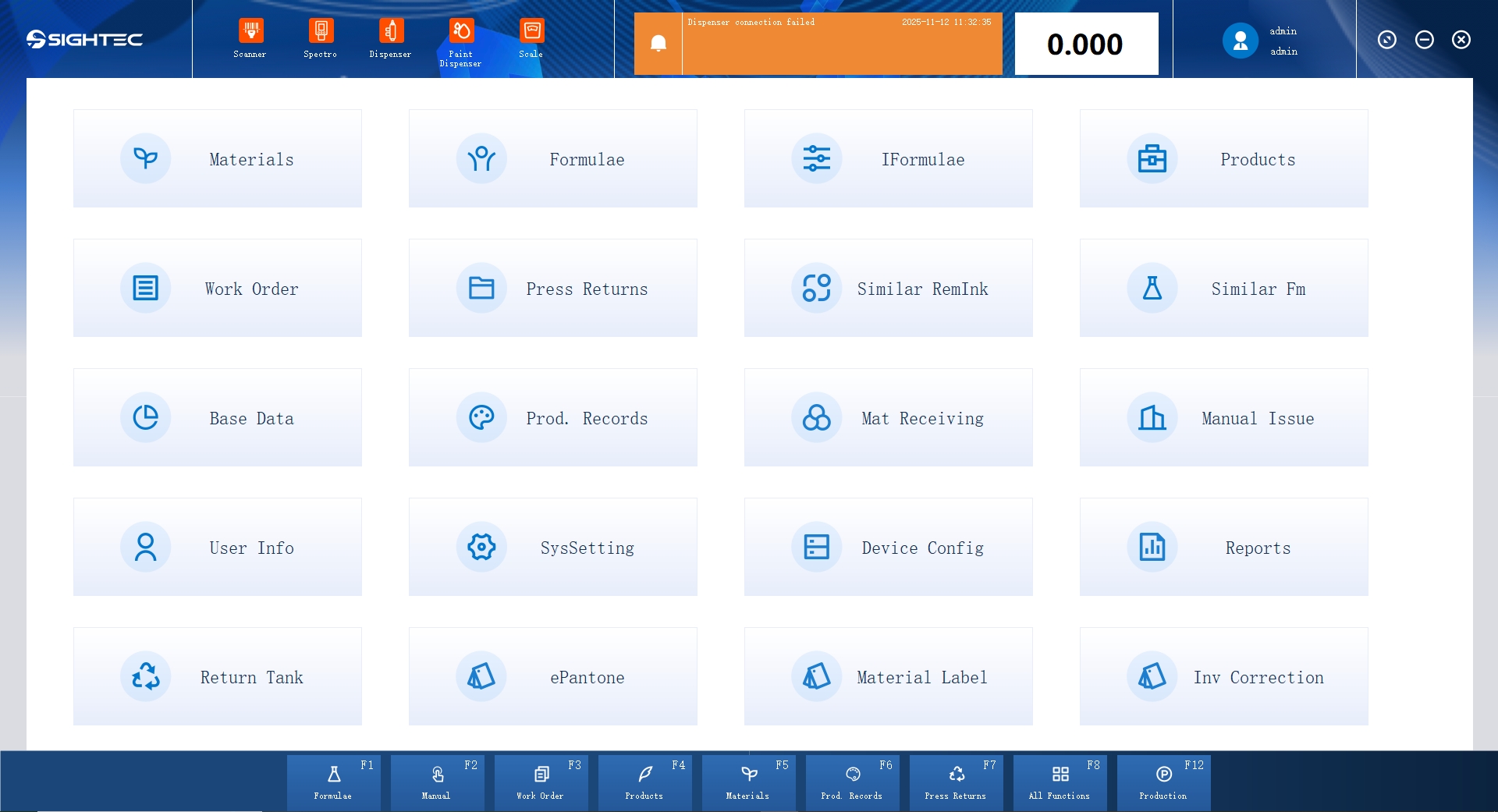

Modern solutions allow you to create digital color definitions based on spectral data—the most accurate description of a color. This enables you to share and approve new colors digitally across your supply chain without shipping physical samples, creating a truly connected and efficient workflow.

Takeaway: Digital discipline in naming and library management is the foundation for a pain-free spot color process.

How you implement spot colors in your design files sets the stage for success or failure in production.

Always select spot colors from your software’s built-in, standardized libraries or load your custom library. Do not manually input CMYK values to approximate a spot color, as this will not result in the correct separate plate.

A critical choice you must make is whether a spot color will print as its own dedicated ink or be converted to a CMYK simulation.

Consider these factors:

Brand Color Accuracy: Crucial brand colors should be preserved as spot colors to guarantee fidelity.

Budget: Each spot color adds a separate plate and ink unit, increasing cost.

Design Effect: Specialty inks like metallics or fluorescents must be run as spot colors.

Modern workflows allow you to define this behavior automatically, ensuring the right outcome for each color.

This is where your digital plans meet physical ink. A robust process here is critical for accuracy and waste reduction.

The accuracy of the physical ink is paramount. An automated ink dispensing system forms the core of a modern color workshop. This system typically consists of a lab verification unit and a bulk production unit.

The Lab Setup for Perfect Formulas:

To ensure every formula is perfect before full-scale production, a professional lab employs: a high-precision dispensing machine (with accuracy as fine as 0.039ml), a flexo/gravure proofer to simulate printing, a spectrophotometer for measurement, specialized color matching software, and a standard light booth for visual assessment.

Two Primary Methods:

Manual Mixing: A skilled ink technician adjusts the mixture by eye, referencing the standard. This is prone to human error and inconsistency.

Computer-Aided Formulation & Automated Dispensing: This is the modern standard. Using spectrophotometers and specialized software, the system calculates a precise recipe. A dispensing machine then executes it with extreme accuracy (e.g., ±1g on a 30kg batch), drastically reducing waste, improving accuracy, and ensuring repeatability.

Accurately proofing a job that uses spot colors on a digital printer is a complex task. Advanced color management systems use spectral data to simulate how the spot color will look when printed with its specific ink.

Keys to Accurate Proofing:

Calibrated Devices: Your proofing printer must be in a perfectly calibrated state.

Advanced Color Rendering: Use systems that employ spectral matching for the most truthful preview.

Substrate Matching: Proof on a paper that is as close as possible to the final production stock.

Press Profiling: A critical step is using a proofer to optimize the color difference data and create a profile that bridges the gap between the digital proof and the actual press, ensuring what you see is truly what you get.

Pain Point: Without a properly calibrated and profiled proofing system, your digital proof is just a guess, not a reliable contract.

Even with perfect preparation, the final output can deviate due to press conditions, substrate, or ink batch variations.

A “nearest color search” function is an invaluable troubleshooting tool. It works by printing a range of color patches around the target spot color. You can then visually or instrumentally select the patch that best matches your desired outcome, and the system will permanently adjust the color output to match that patch.

For the highest level of output consistency, optical feedback systems are used. These systems employ inline spectrophotometers that constantly measure color control strips on the press sheet.

Sophisticated software makes micro-adjustments to the ink keys in real-time, maintaining color stability throughout the print run without the human eye perceiving any fluctuation.

Takeaway: Proactive adjustment tools and automated control systems are your best defense against unpredictable output results.

Maintaining color consistency during a print run and from one job to the next is the final hurdle.

The Control Method:

A proven method involves printing specific control color patches on every sheet. A scanning spectrophotometer measures these patches and feeds the data back to the press control system.

This system compares the live measurements to the target values and automatically makes corrections to the ink flow. This creates a “closed loop” of continuous quality control.

Benefits of This Approach:

Dramatically Reduces Waste: Fewer manual adjustments mean less paper and ink are wasted at startup. This directly contributes to a higher first-time success rate, allowing over 80% of jobs to be approved on the first pass.

Increases Productivity: The press operator can focus on other tasks, confident that color is being managed automatically.

Guarantees Consistency: The color you sign off on at the start of the run is the color you get at the end.

To achieve end-to-end color control, you must institutionalize your process with a clear protocol.

Document a standard operating procedure (SOP) for every step: color selection, digital file creation, approval, and production. Define quality checkpoints and responsibilities. A key part of this is establishing a color difference database, verifying new formulas, and creating digital archives for every color.

Create a strict schedule for calibrating all devices in your workflow—monitors, proofers, and presses. Consistency at every stage is non-negotiable.

Ensure everyone involved understands color principles, knows how to use the tools, and can troubleshoot common problems. This includes comprehensive training on the operations of automated dispensing system software and color matching software. A skilled team is your most valuable asset in color management.

Managing spot colors is a complex journey from a digital idea to a physical reality. By mastering this workflow—from disciplined digital asset management and precision ink dispensing in the lab to stable press output—you transform color from a variable into a guarantee.

The future of spot color management is digital, spectral, and interconnected. Embracing this data-driven approach is no longer optional for brands and printers who demand efficiency, accuracy, and brilliant results.

Ready to Take Control of Your Color and Your Bottom Line?

Eliminate costly mistakes and disappointing results. An integrated automated ink dispensing system is the key to achieving this. It delivers tangible value by:

Boosting Your First-Pass Success Rate to over 80%, slashing material waste and press time.

Enabling On-Demand Production of ink, minimizing leftover ink and ensuring perfect batch-to-batch consistency.

Managing Residual Ink intelligently, keeping this costly inventory at the absolute minimum.

Integrating with your ERP for seamless order management, batch production, and precise cost accounting for every single job.

Let our experts help you build a robust color management workflow tailored to your needs.

[Download Our Free Color Consistency Checklist] or [Contact Us for a Custom Workflow Assessment] today!